Answer is:

Any of the above

Explanation:

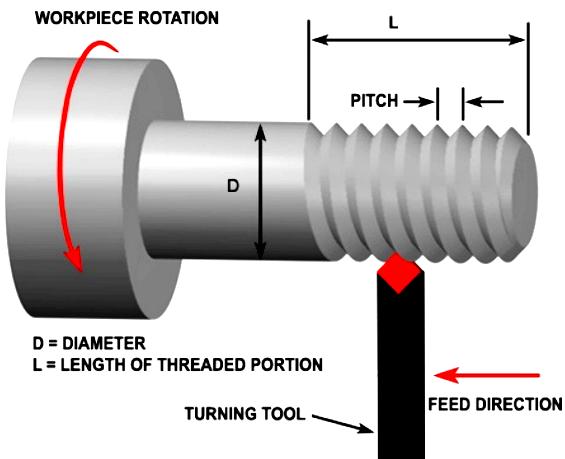

Incorrect pitch of thread during thread cutting with single point tool due to

Incorrect selection of change gears

Lead screw worn out

Half nut worn out

Answer is:

Any of the above

Explanation:

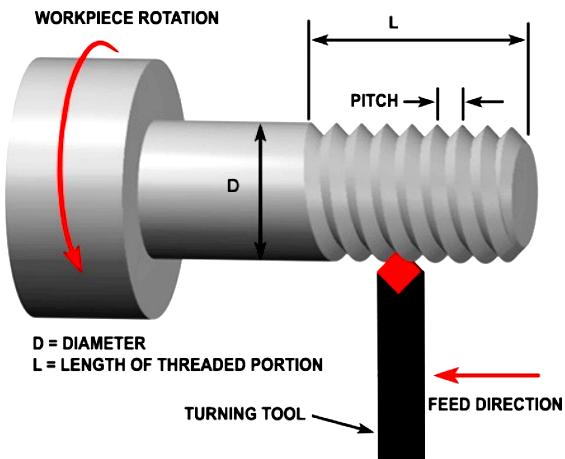

Reason for torn threads while thread cutting on lathe can be due to

Blunt tool

Heavy depth of cut

Insufficient side clearance

Answer is:

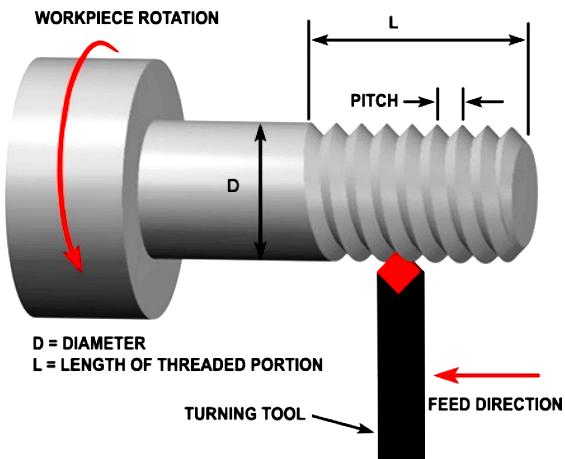

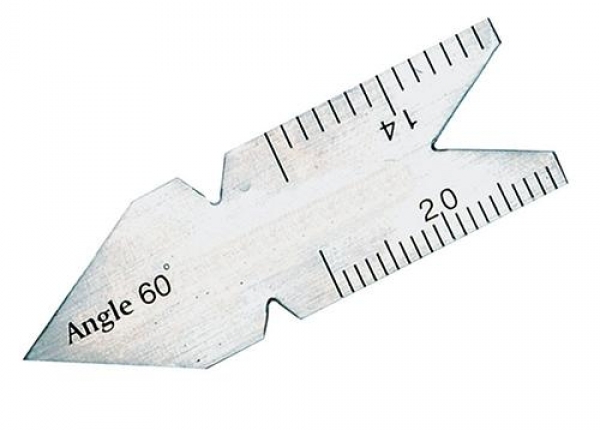

centre gauge

Explanation:

For setting of tool for threading, it is aligned with the work by using centre gauge.

Answer is:

Same tool is used for cutting external and internal threads

Explanation:

Different tool types are required for cutting external and internal threads.

Answer is:

less than that for the plain turning operation

Explanation:

While cutting internal threads on lathe with single point tool, the spindle speed should be less than that for the plain turning operation.