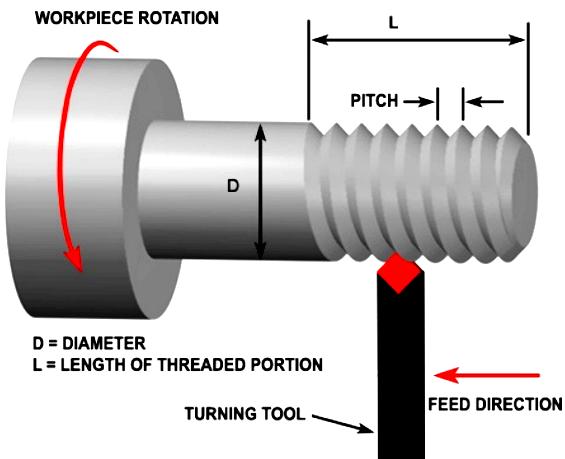

Incorrect pitch of thread during thread cutting with single point tool due to

Incorrect selection of change gears

Lead screw worn out

Half nut worn out

16) Which among the following is the cause for incorrect pitch of thread during thread cutting with single point tool ?

Answer is:

Any of the above

Explanation:

Related Lathe Operations MCQ with Answers

Answer is:

Any of the above

Explanation:

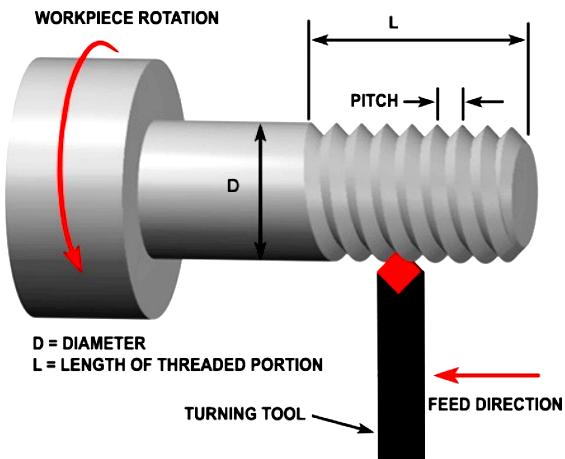

Reason for torn threads while thread cutting on lathe can be due to

Blunt tool

Heavy depth of cut

Insufficient side clearance

Answer is:

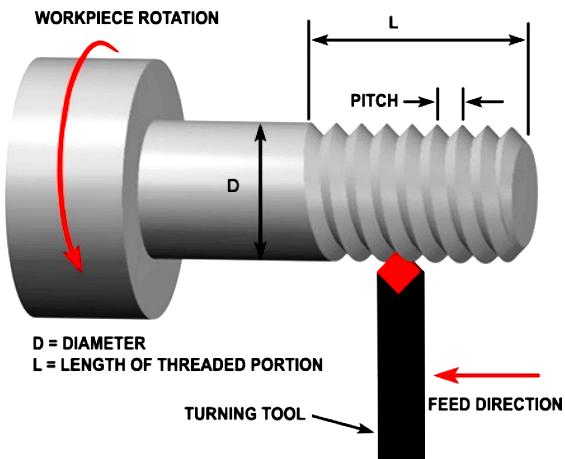

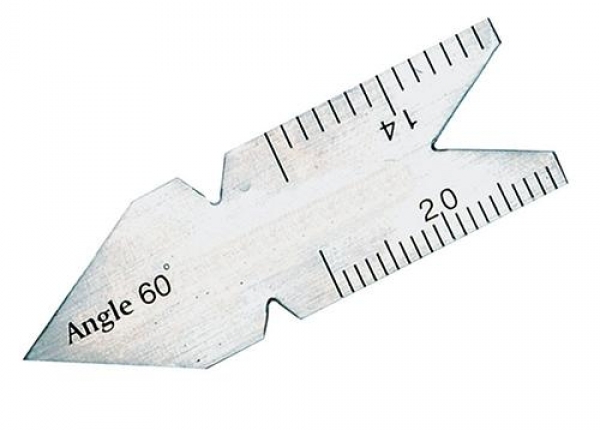

centre gauge

Explanation:

For setting of tool for threading, it is aligned with the work by using centre gauge.

Answer is:

Same tool is used for cutting external and internal threads

Explanation:

Different tool types are required for cutting external and internal threads.

Answer is:

less than that for the plain turning operation

Explanation:

While cutting internal threads on lathe with single point tool, the spindle speed should be less than that for the plain turning operation.