Work hardening is that which occurs in metalworking processes that intentionally induce plastic deformation to exact a shape change. These processes are known as cold working or cold forming processes. The cold working of the metal increases the hardness, yield strength, and tensile strength.

18) cold working of metal increases

all of these

Related Workshop Technology MCQ with Answers

all of the above

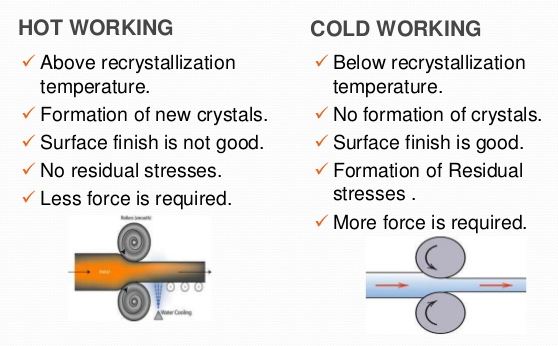

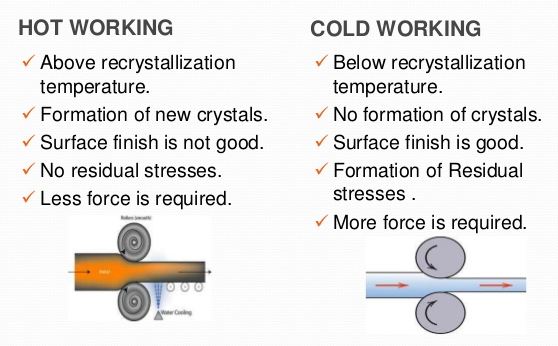

Cold working is the plastic deformation of metals below the recrystallization temperature. In most cases, such cold forming is done at room temperature. The major cold-working operations can be classified basically as squeezing, bending, shearing and drawing.

is used for reducing the diameters of round bars and tubes by rotating dies which open and close rapidly on the work

Rotary swaging Is used for reducing the diameters of round bars and a tube by rotating dies which open and close rapidly on the work.

consists of pressing the metal inside a chamber to force it out by high pressure through an orifice which is shaped to provide the desired from of the finished parts

Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed through a die of the desired cross-section.

Extrusion is Consists of pressing the metal inside a chamber to force it out by high pressure through an orifice which is shaped to provide the desired form of the finished part.

cold peening

The process used to improve fatigue resistance of the metal by setting up compressive stresses in its surface, is known as Cold peening.