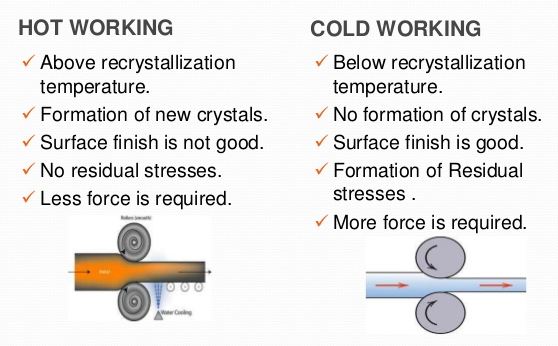

Cold working is the plastic deformation of metals below the recrystallization temperature. In most cases, such cold forming is done at room temperature. The major cold-working operations can be classified basically as squeezing, bending, shearing and drawing.

19) during cold working process

Answer is:

all of the above

Explanation:

Related Workshop Technology MCQ with Answers

Answer is:

is used for reducing the diameters of round bars and tubes by rotating dies which open and close rapidly on the work

Explanation:

Rotary swaging Is used for reducing the diameters of round bars and a tube by rotating dies which open and close rapidly on the work.

Answer is:

consists of pressing the metal inside a chamber to force it out by high pressure through an orifice which is shaped to provide the desired from of the finished parts

Explanation:

Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed through a die of the desired cross-section.

Extrusion is Consists of pressing the metal inside a chamber to force it out by high pressure through an orifice which is shaped to provide the desired form of the finished part.

Answer is:

cold peening

Explanation:

The process used to improve fatigue resistance of the metal by setting up compressive stresses in its surface, is known as Cold peening.

Answer is:

cold heading

Explanation:

The process extensively used for making bolts and nuts is cold heading.