The process used to improve fatigue resistance of the metal by setting up compressive stresses in its surface, is known as Cold peening.

22) The process used to improve fatigue resistance of the metal by setting up compressive stresses in its surface, is known as

cold peening

Related Workshop Technology MCQ with Answers

cold heading

The process extensively used for making bolts and nuts is cold heading.

upsetting

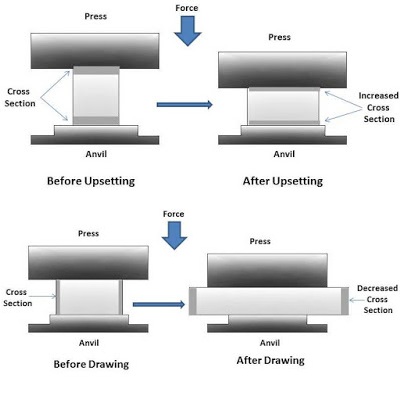

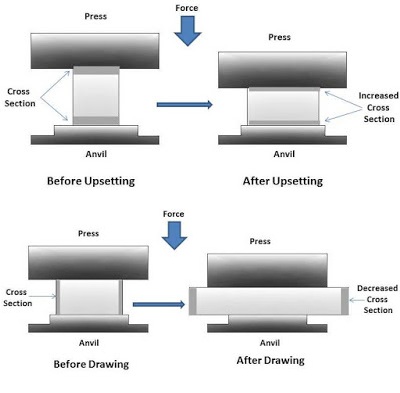

1)Drawing Down: Drawing down is a process of elongate the length and reduce the cross section area of work piece. Simply in this operation, the length of work piece increases and the cross section area decreases. In this process, a compressive force is applied at perpendicular direction of its length axis. If a tensile force is applied to change its length at parallel to its length axis, this process is known as wire drawing.

2) Upsetting: Upsetting is just opposite operation to drawing down. In this operation, the length of work piece decreases and its cross section area increases. In this process, a compressive force is applied at parallel direction to its length axis.

drawing down

1)Drawing Down: Drawing down is a process of elongate the length and reduce the cross section area of work piece. Simply in this operation, the length of work piece increases and the cross section area decreases. In this process, a compressive force is applied at perpendicular direction of its length axis. If a tensile force is applied to change its length at parallel to its length axis, this process is known as wire drawing.

2) Upsetting: Upsetting is just opposite operation to drawing down. In this operation, the length of work piece decreases and its cross section area increases. In this process, a compressive force is applied at parallel direction to its length axis.

tube drawing

A moving mandrel is used in Tube drawing.