cast iron

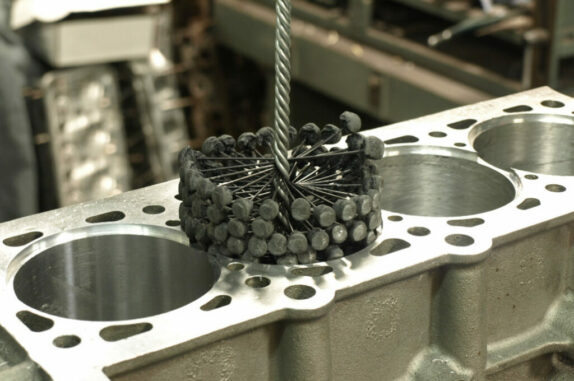

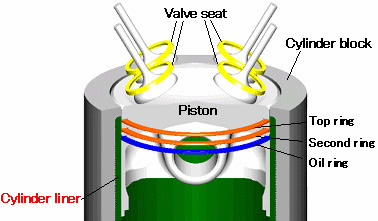

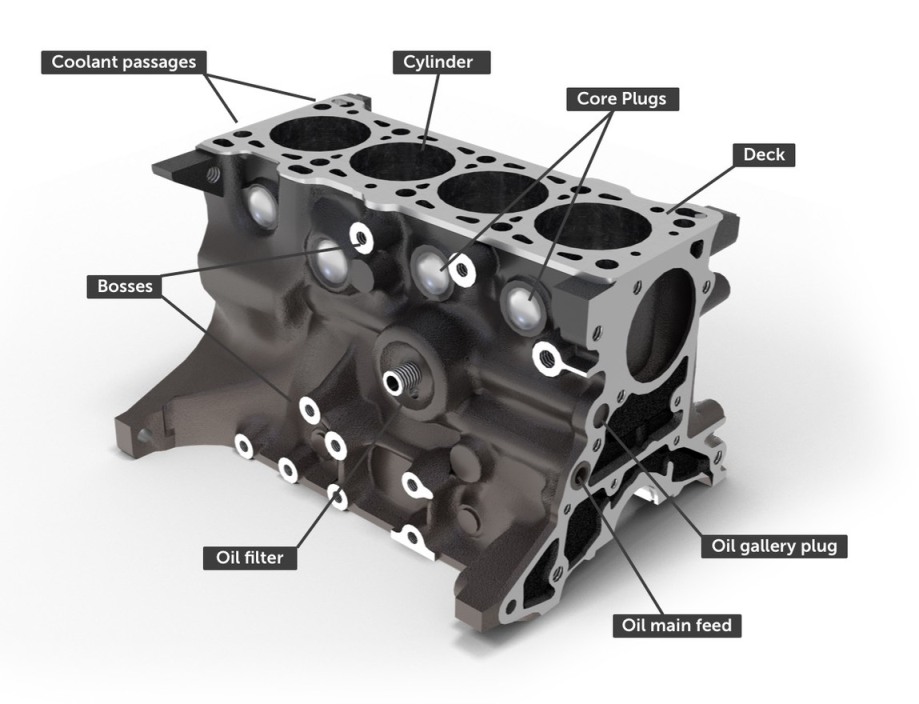

A cylinder liner is a cylindrical part to be fitted into an engine block to form a cylinder. It is one of the most important functional parts to make up the interior of an engine. This is called Cylinder liner in Japan, but some countries(or companies) call this Cylinder sleeve.

A cylinder wall in an engine is under high temperature and high pressure, with the piston and piston rings sliding at high speeds. In particular, since longer service life is required of engines for trucks and buses, cast iron cylinders that have excellent wear-resistant properties are only used for cylinder parts.

Also, with the recent trend of lighter engines, materials for engine blocks have been shifting from cast iron to aluminum alloys. However, as the sliding surface for the inner cylinder, the direct sliding motion of aluminum alloys has drawbacks in deformation during operation and wear-resistance. For that reason, cast iron cylinder liners are used in most cases.

Hence In aluminium cylinder blocks, the cylinder liners are made of cast iron.

it is lighter and have good heat dissipation characteristics

The aluminium alloy is used in cylinder blocks because it is lighter and have good heat dissipation characteristics

cast iron

The material generally used for cylinder sleeves is cast iron.

resistance to wear

the characteristic that is enhanced by the use of cylinder sleeves is resistance to wear.

honing

The reconditioning process used to give cylinder bore surfaces a cross hatch pattern, is known as honing.