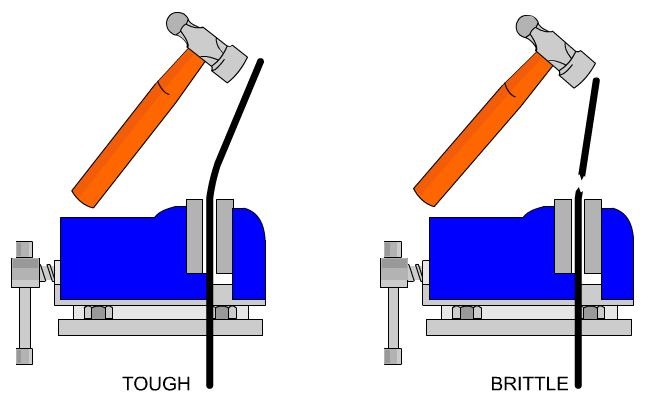

Toughness:

When a huge external force is applied on a metal, the metal will experience fracture. Toughness is the ability of a metal to resist fracture. The ability of a material to resist fracture due to high impact loads, is called toughness.

Strength:

When external forces are applied on a metal, breaking (brittle metal) or yielding (ductile metal) may occur. Strength is the property of a metal by which it resists external force without breaking or yielding.

Stiffness:

When an external force is applied on a metal, it develops an internal resistance. The internal resistance developed per unit area is called stress. Stiffness is the ability of a metal to resist deformation under stress.

Plasticity:

Plasticity is the property by which a metal retains its deformation permanently, when the external force applied on it is removed.

Examples: forming, forging, hammering

16) The ability of a material to resist fracture due to high impact load is called

toughness

Related KPSC ITI JTO Turner Question Papers - 2018 with Answer Key

nickel steel

It can be said that the pendulum clock is made up of invar because invar's coefficient of thermal expansion is small. So, the length of the pendulum remains unaffected during changes in temperature. Invar is derived from the word invariable. It is an alloy which is made from nickel and iron. It has a low coefficient of thermal expansion. So, there will not be linear expansion of the pendulum due to the rise in temperature. And the time shown in the clock will be accurate. Thus, invar is used in the pendulum of the clock. Invar, also known as Nickel Alloy 36, is a nickel-iron alloy noted for its uniquely low coefficient of thermal expansion.

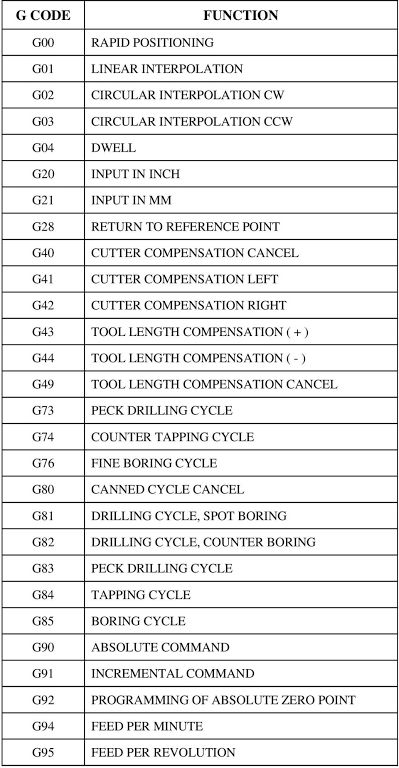

circular interpolation counter-clockwise

G00 - Move in a straight line at rapids speed.

G01 - Linear Interpolation at specified feed rate.

G02 - Circular Interpolation (Clockwise)

G03 - Circular Interpolation (Counter-Clockwise)

It is an integral part of the apron

1 degree 55 minutes

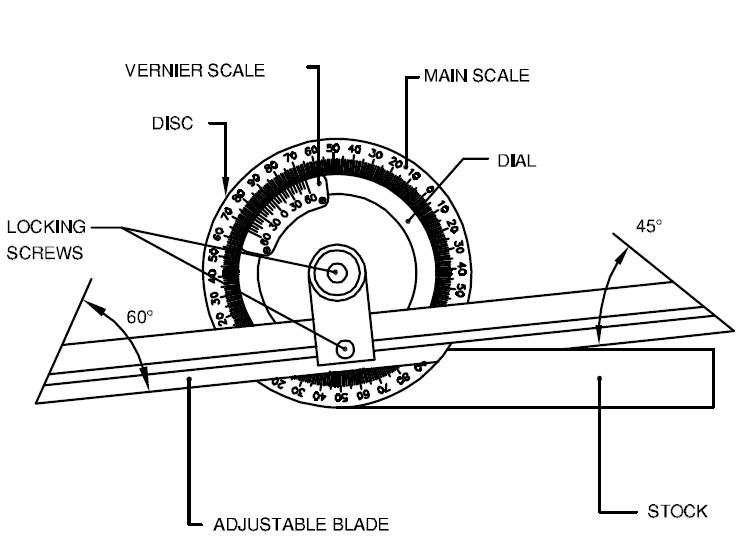

The vernier bevel protractor is a precision instrument meant for measuring angles to an accuracy of 5 minutes.

The Least count of vernier bevel protractor is 5' (Five Minutes)

The value of each Vernier scale division of Vernier bevel protractor is 1 degree 55 minutes.

To get the least count of 5 minutes (5') in a vernier bevel protractor the 23 degree main scale is divided into 12 equal parts on vernier scale.

Following are the parts of a vernier bevel protractor.

Stock : – This is one of the contacting surfaces during the measurement of an angle. Preferably it should be kept in contact with the datum surface from which the angle is measured.

Dial:– The dial is an integrated part of the stock. It is circular in shape, and the edge is graduated in degrees.

Blade:- This is the other surface of the instrument that contacts the work during measurement. It is fixed to the dial with the help of the clamping lever. A parallel groove is provided in the centre of the blade to enable it to be longitudinally positioned whenever necessary.

Locking Screws:- Two knurled locking screws are provided, one to lock the dial to the disc, and the other to lock the blade to the dial.