9) Cutting forces at the cutting tool can be measured by

A dynamometer

Related KPCL JE Mechanical Question Paper - 2018 with Answer Key

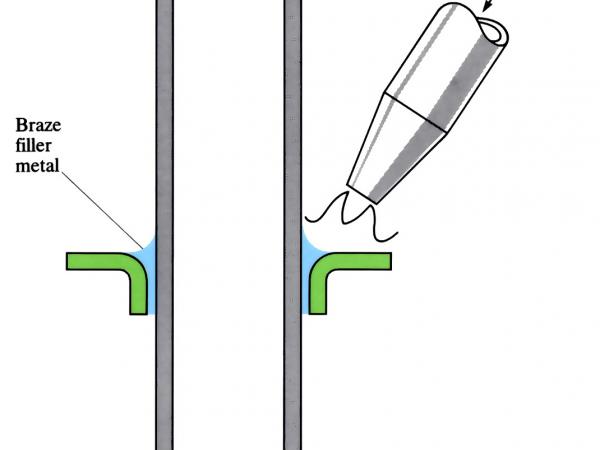

Brazing

Brazing is a method of joining metal surface by introducing a non ferrous alloy with melting point above 400° C.

Which takes the form of internal voids of surface depression due to excessive gaseous material not able to escape

When gases entrapped on the surface of the casting due to solidifying metal, a rounded or oval cavity is formed called as blowholes. These defects are normally present in the cope part of the mold.

Ductile material

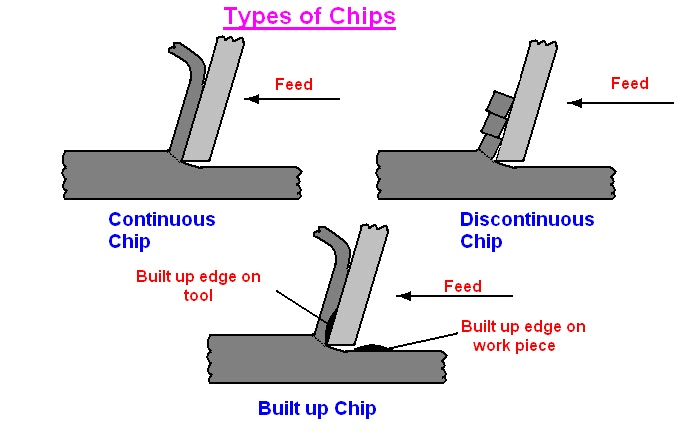

Discontinuous chips Discontinuous chips are usually formed during machining of brittle materials like cast iron. The low cutting speed and small rake angle of the tool are responsible for the formation of discontinuous chips.

Continuous chips Continuous chips are produced during machining of ductile materials like mild steel. The high cutting speed and large rake angle of the tool will result in the formation of continuous chips. These chips are in the form of long coils having the same thickness throughout.

Continuous chips with built up edge Continuous chips with built up edge are also produced during machining of ductile materials. The low cutting speed and small rake angle of the tool will result in the formation of continuous chips with built up edge. These chips are also formed when the cutting edge of the tool is dull.