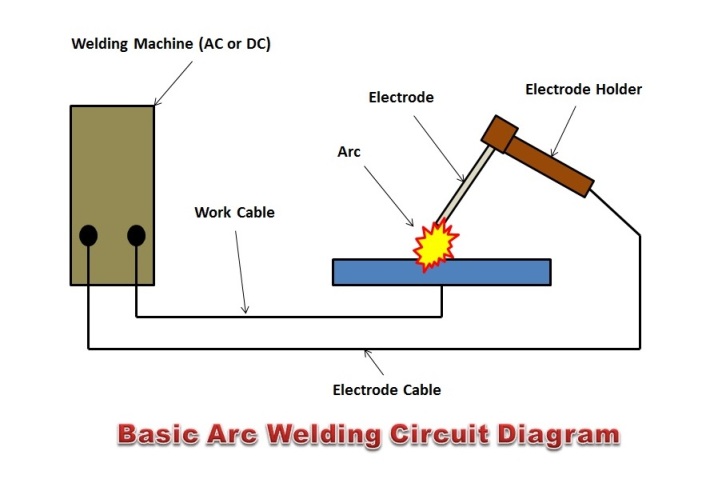

Arc welding is a welding process that is used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals when cool result in a binding of the metals. It is a type of welding that uses a welding power supply to create an electric arc between a metal stick ("electrode") and the base material to melt the metals at the point of contact. Arc welders can use either direct (DC) or alternating (AC) current, and consumable or non-consumable electrodes.

In an arc welding process, the three variables to be essentially controlled to obtain a satisfactory weldment are welding current, voltage and speed.

1) In an arc welding process, the three variables to be essentially controlled to obtain a satisfactory weldment are

Welding current, voltage and speed

Related ISRO Technician-B Welder Question Paper - 2017 (Set -1) with Answer Key

Width of weld to the depth

In fusion welding process, penetration is the ratio of width of weld to the depth.

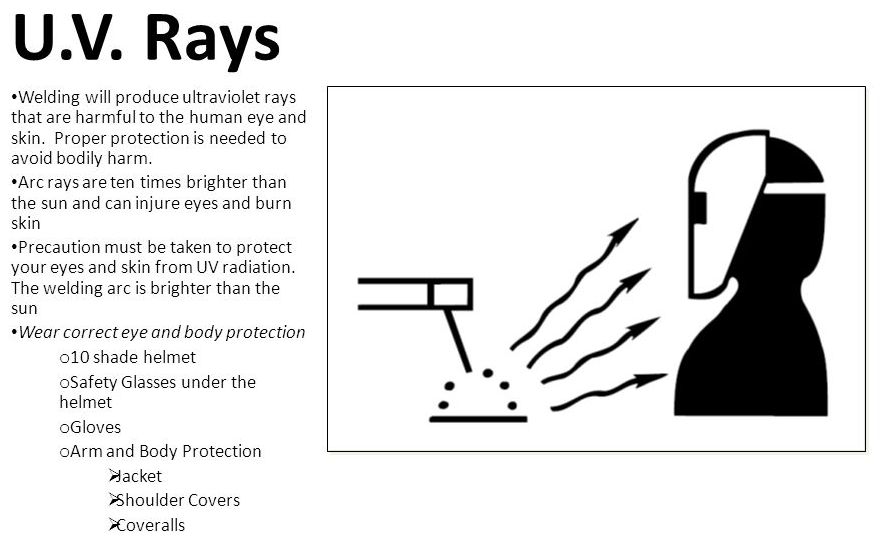

Ultraviolet(UV)

Welding arcs give off radiation over a broad range of wavelengths - from 200 nm (nanometres) to 1,400 nm (or 0.2 to 1.4 µm, micrometres). These ranges include ultraviolet (UV) radiation (200 to 400 nm), visible light (400 to 700 nm), and infrared (IR) radiation (700 to 1,400 nm).

UV-radiation is divided into three ranges - UV-A (315 to 400 nm), UV-B (280 to 315 nm) and UV-C (100 to 280 nm). UV-C and almost all UV-B are absorbed in the cornea of the eye. UV-A passes through cornea and is absorbed in the lens of the eye.

Some UV radiation, visible light, and IR radiation can reach the retina.

Certain types of UV radiation can produce an injury to the surface and mucous membrane (conjunctiva) of the eye called "arc eye," "welders' eye" or "arc flash." These names are common names for "conjunctivitis" - an inflammation of the mucous membrane of the front of the eye.

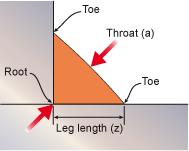

Leg length

The distance between the root and toe of a fillet weld is called leg length.

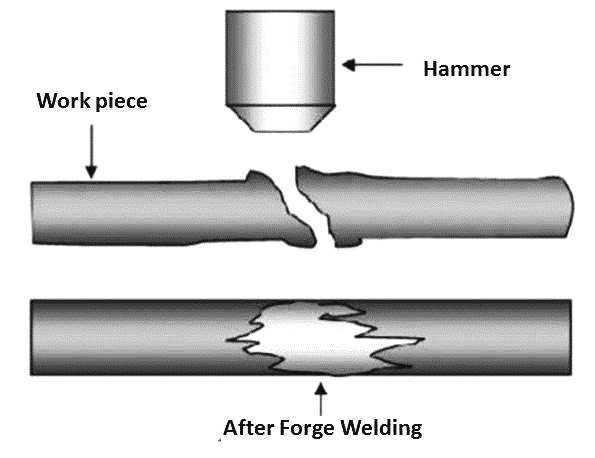

Fusion welding with pressure

Forge welding is a solid-state welding process that joins two pieces of metal by heating them to a high temperature and then hammering them together. It may also consist of heating and forcing the metals together with presses or other means, creating enough pressure to cause plastic deformation at the weld surfaces.