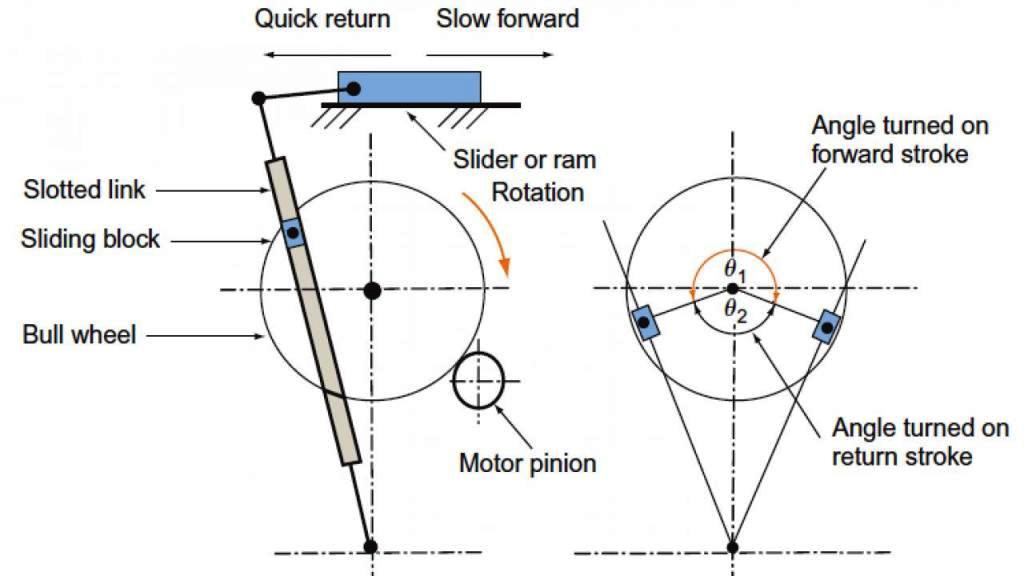

During the return stroke, the mechanism is so designed to make the tool move at a faster rate to reduce the idle return time. This mechanism is known as quick return mechanism. As the ram moves at a faster rate during return stroke, the time taken becomes less.

2) Quick return mechanism in a planing machine is necessary to

Reduce operation time

ISRO Technician-B Machinist Question Paper - 2019 (Set -1) with Answer Key

For more MCQ's Click HereRelated ISRO Technician-B Machinist Question Paper - 2019 (Set -1) with Answer Key

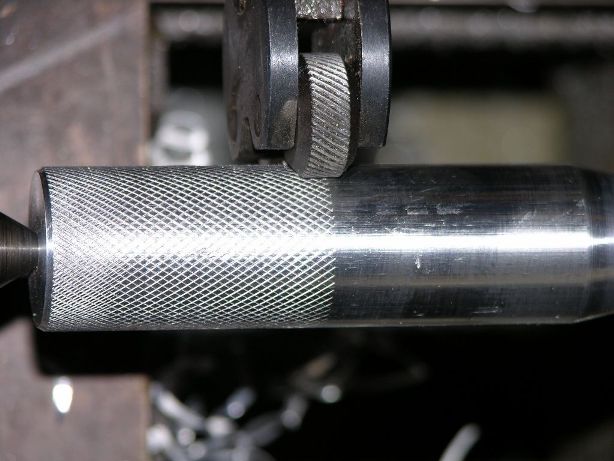

Lathe

Knurling is a process of impressing a diamond shaped or straight line pattern into the surface of a workpiece by using specially shaped hardened metal wheels to improve its appearance and to provide a better gripping surface.

Knurling operation is done on lathe machine.

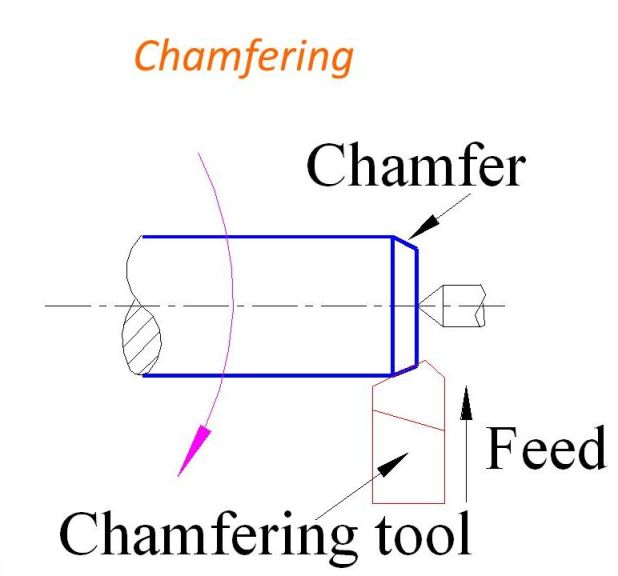

Chamfering

Chamfering: Chamfering is the operation of beveling the extreme end of the work piece. The form tool used for taper turning may be used for this purpose. Chamfering is an essential operation after thread cutting so that the nut may pass freely on the threaded work piece.

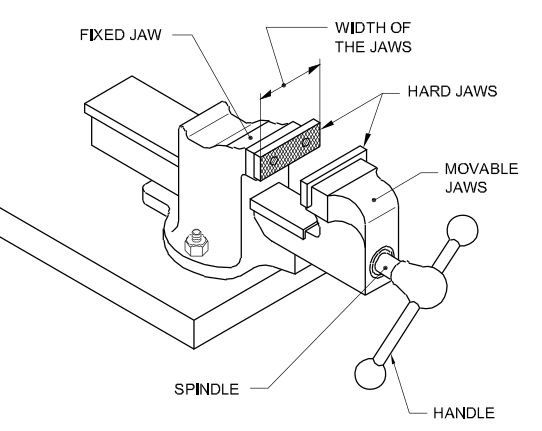

Width of jaws

The size of the engineer's vice is stated by the width of the jaws.eg. 150mm parallel jaw bench vice.

Heavy volume of material can be removed

A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the material.

It is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece.

Generally, the grinding is finishing operation to show the high surface quality, accuracy of the shape and dimension.