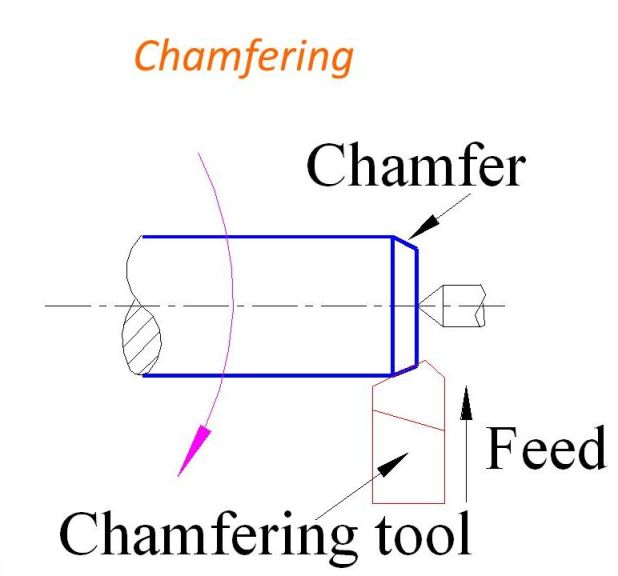

Chamfering: Chamfering is the operation of beveling the extreme end of the work piece. The form tool used for taper turning may be used for this purpose. Chamfering is an essential operation after thread cutting so that the nut may pass freely on the threaded work piece.

4) Bevelling the edge of the cylindrical job is called

Chamfering

ISRO Technician-B Machinist Question Paper - 2019 (Set -1) with Answer Key

For more MCQ's Click HereRelated ISRO Technician-B Machinist Question Paper - 2019 (Set -1) with Answer Key

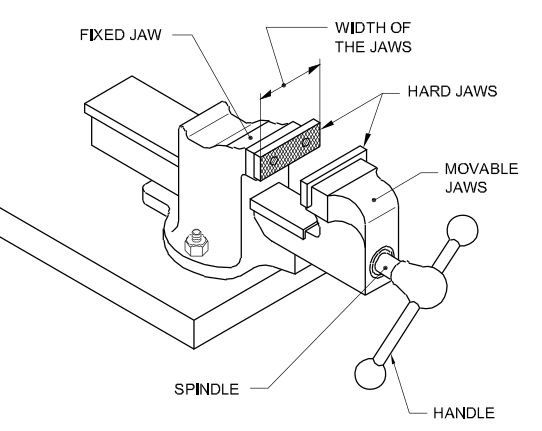

Width of jaws

The size of the engineer's vice is stated by the width of the jaws.eg. 150mm parallel jaw bench vice.

Heavy volume of material can be removed

A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the material.

It is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece.

Generally, the grinding is finishing operation to show the high surface quality, accuracy of the shape and dimension.

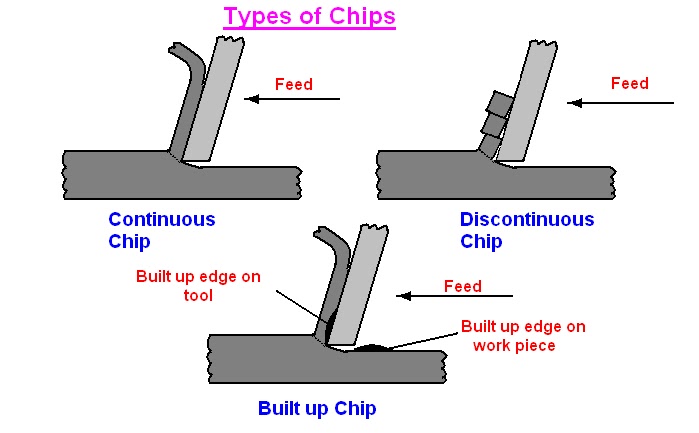

Brittle material

Discontinuous chips Discontinuous chips are usually formed during machining of brittle materials like cast iron. The low cutting speed and small rake angle of the tool are responsible for the formation of discontinuous chips.

Continuous chips Continuous chips are produced during machining of ductile materials like mild steel. The high cutting speed and large rake angle of the tool will result in the formation of continuous chips. These chips are in the form of long coils having the same thickness throughout.

Continuous chips with built up edge Continuous chips with built up edge are also produced during machining of ductile materials. The low cutting speed and small rake angle of the tool will result in the formation of continuous chips with built up edge. These chips are also formed when the cutting edge of the tool is dull.

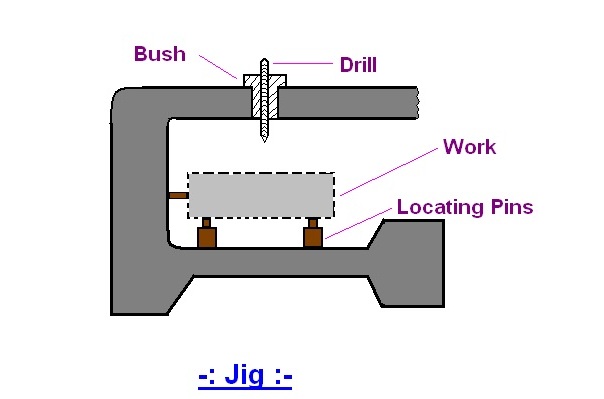

Holding the work piece and guide the tool

A jig is a work-holding device that holds, supports, and locates the workpiece and guides the one or more tools to perform a specific operation.

A fixture is a work-holding device that only holds, supports, and locates the workpiece, but does not guide the tools to perform a specific operation.