Work study consists of two techniques namely method study and work measurement.

The method study is a technique to simplify the job and develop more economical methods of doing it. Work study is concerned with improving present method and finding standard time.

The Work measurement is concerned with the elimination of ineffective time and establishment of time standards for a job.

Work study is mainly aimed at determining the most efficient method of performing a job. Basic tool in work study is stop watch.

7) Work study is concerned with

improving present method and finding standard time

Related Production and Industrial Engineering MCQ with Answers

stop watch

Work study consists of two techniques namely method study and work measurement.

The method study is a technique to simplify the job and develop more economical methods of doing it.

The Work measurement is concerned with the elimination of ineffective time and establishment of time standards for a job.

Work study is mainly aimed at determining the most efficient method of performing a job. Basic tool in work study is stop watch.

operation

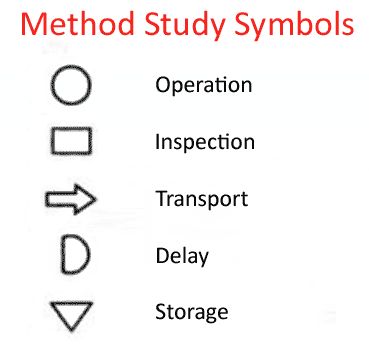

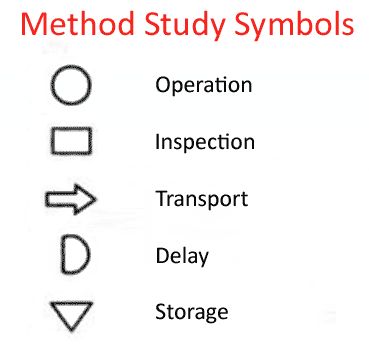

1. Operation: An operation is an action performed for advancing towards desired result. This indicates the main steps in a process, method or procedure.

2.Inspection: An inspection occurs when the product is removed for a time for production. It includes the visual observations for finish, checking the dimensions etc.

3.Storage: A storing occurs when the product is removed for a time from production. For example, materials kept in stores to be distributed to various work.

4.Delay: A delay occurs when some undesirable event prevents or hinders the next planned activity e.g. waiting for a machine to be repaired. A traffic jam. Work waiting between consecutive operations.

5. Transport : A transport occurs when there is movement from one place to another. It indicates the movement of materials from one work station to another.

delay temporary storage

1. Operation: An operation is an action performed for advancing towards desired result. This indicates the main steps in a process, method or procedure.

2.Inspection: An inspection occurs when the product is removed for a time for production. It includes the visual observations for finish, checking the dimensions etc.

3.Storage: A storing occurs when the product is removed for a time from production. For example, materials kept in stores to be distributed to various work.

4.Delay: A delay occurs when some undesirable event prevents or hinders the next planned activity e.g. waiting for a machine to be repaired. A traffic jam. Work waiting between consecutive operations.

5. Transport : A transport occurs when there is movement from one place to another. It indicates the movement of materials from one work station to another.

minimum value

In perpetual inventory control, the material is checked as it reaches its Minimum value.