Work study consists of two techniques namely method study and work measurement.

The method study is a technique to simplify the job and develop more economical methods of doing it.

The Work measurement is concerned with the elimination of ineffective time and establishment of time standards for a job.

Work study is mainly aimed at determining the most efficient method of performing a job. Basic tool in work study is stop watch.

142) Basic tool in work study is

stop watch

Related Production and Industrial Engineering MCQ with Answers

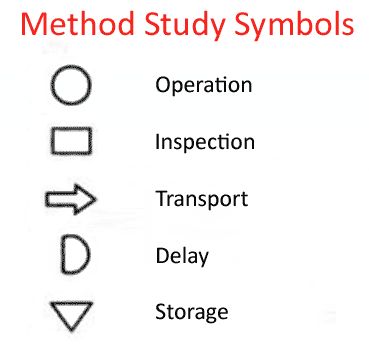

operation

1. Operation: An operation is an action performed for advancing towards desired result. This indicates the main steps in a process, method or procedure.

2.Inspection: An inspection occurs when the product is removed for a time for production. It includes the visual observations for finish, checking the dimensions etc.

3.Storage: A storing occurs when the product is removed for a time from production. For example, materials kept in stores to be distributed to various work.

4.Delay: A delay occurs when some undesirable event prevents or hinders the next planned activity e.g. waiting for a machine to be repaired. A traffic jam. Work waiting between consecutive operations.

5. Transport : A transport occurs when there is movement from one place to another. It indicates the movement of materials from one work station to another.

delay/temporary storage

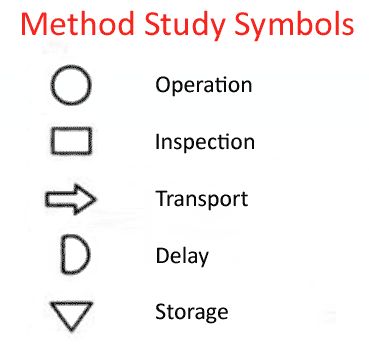

1. Operation: An operation is an action performed for advancing towards desired result. This indicates the main steps in a process, method or procedure.

2.Inspection: An inspection occurs when the product is removed for a time for production. It includes the visual observations for finish, checking the dimensions etc.

3.Storage: A storing occurs when the product is removed for a time from production. For example, materials kept in stores to be distributed to various work.

4.Delay: A delay occurs when some undesirable event prevents or hinders the next planned activity e.g. waiting for a machine to be repaired. A traffic jam. Work waiting between consecutive operations.

5. Transport : A transport occurs when there is movement from one place to another. It indicates the movement of materials from one work station to another.

permanent storage

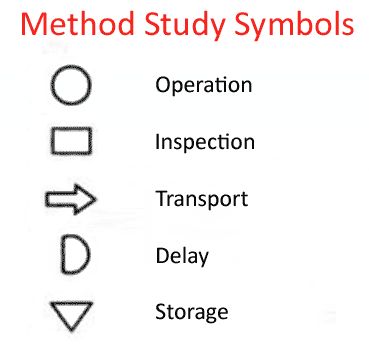

1. Operation: An operation is an action performed for advancing towards desired result. This indicates the main steps in a process, method or procedure.

2.Inspection: An inspection occurs when the product is removed for a time for production. It includes the visual observations for finish, checking the dimensions etc.

3.Storage: A storing occurs when the product is removed for a time from production. For example, materials kept in stores to be distributed to various work.

4.Delay: A delay occurs when some undesirable event prevents or hinders the next planned activity e.g. waiting for a machine to be repaired. A traffic jam. Work waiting between consecutive operations.

5. Transport : A transport occurs when there is movement from one place to another. It indicates the movement of materials from one work station to another.

overhead crane

Overhead crane is used for lifting loads and transport to another location.

An overhead crane, commonly called a bridge crane, is a type of crane found in industrial environments. An overhead crane consists of parallel runways with a traveling bridge spanning the gap. A hoist, the lifting component of a crane, travels along the bridge. If the bridge is rigidly supported on two or more legs running on a fixed rail at ground level, the crane is called a gantry crane or a goliath crane.