Oblique cutting

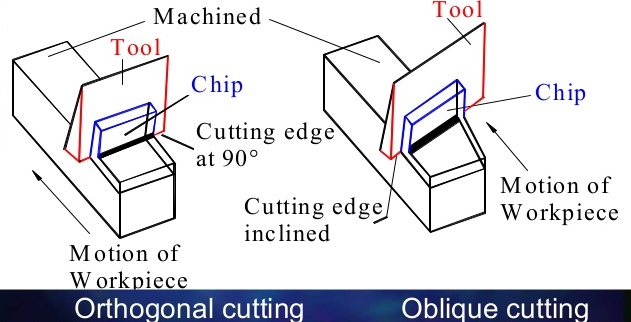

Following are the two methods of metal cutting depending upon the arrangement of cutting edge with respect to the direction of tool travel:

1. Orthogonal cutting or two dimensional cutting.

In orthogonal cutting, the cutting edge of the tool is perpendicular to the direction of tool travel. The cutting edge clears the width of the workpiece on either ends. The chip flows over the tool face and the direction of the chip flow velocity is normal to the cutting edge. The maximum chip thickness occurs at the middle. In orthogonal cutting, the shear angle is the angle between the rake face and the shear plane.

2. Oblique cutting or three dimensional cutting.

In oblique cutting, the cutting edge of the tool is inclined at an angle less than 90° to the direction of tool travel. Frequently, more than one cutting edges are in action. The cutting edge may not clear the width of the work piece. The chip flows

on the tool face at an angle less than 90° with the normal on the cutting edge. The maximum chip thickness may not occur at the middle.

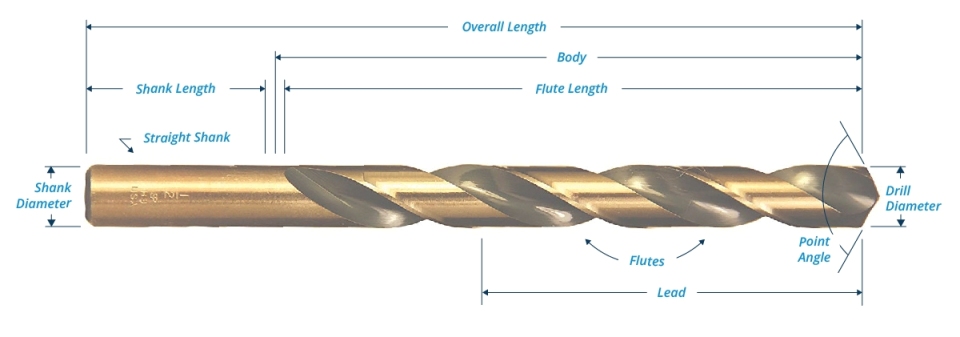

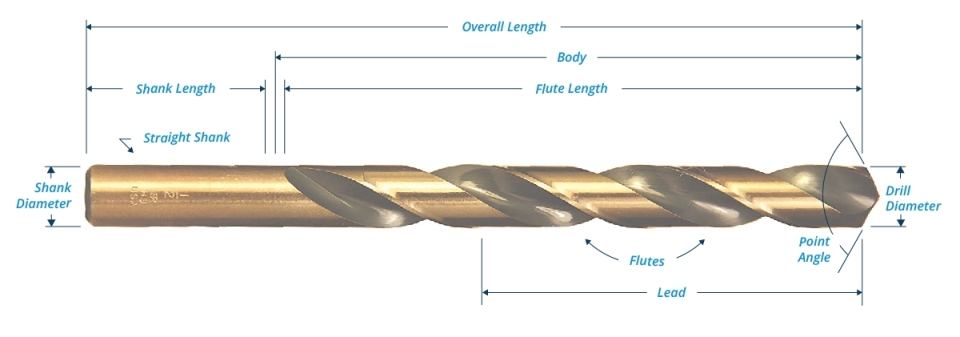

flutes

Flutes are the spiral grooves which run to the length of the drill. The flutes helps to

1. To form the cutting edges

2. To curl the chips and allow these to come out

3. The coolant to flow to the cutting edge.

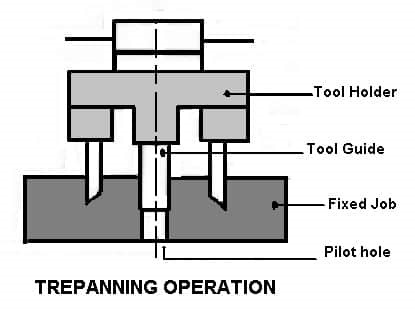

Producing a hole by removing metal along the circumference of a hollow cutting tool.

Trepanning is an operation of producing a hole by removing metal along the circumference of a hollow cutting tool.

flutes

Flutes are the spiral grooves which run to the length of the drill. The flutes helps to

1. To form the cutting edges

2. To curl the chips and allow these to come out

3. The coolant to flow to the cutting edge.