Answer is:

Hard and brittle

Explanation:

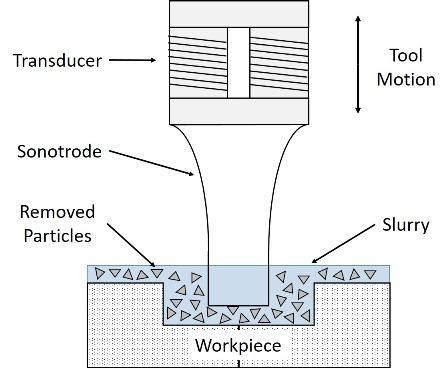

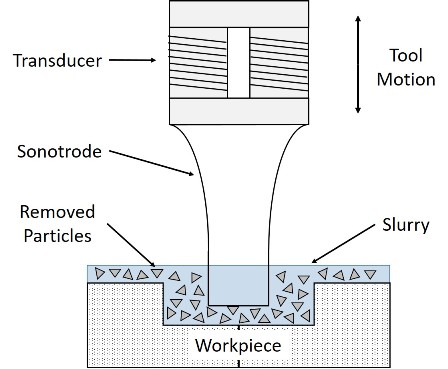

In Ultrasonic machining, the metal is removed by using abrasive slurry between the tool and work. The abrasive slurry contains fine particles of aluminium oxide or silicon carbide or boron carbide and water. The vibratory tool (made of brass or copper) striking on the flow of abrasive slurry, causes thousands of microscopic abrasive grains to remove the work material by abrasion. The ultrasonic machining is best suited for tool steels, sintered carbides, glass, plastics etc. This type of machining may be used for machining of hard and brittle materials. Ultrasonic machining cuts materials at very slow speeds and produces good surface finish.