parting sand

A pure silica sand employed on the faces of the pattern before moulding is known as parting sand.

When the pattern is withdrawn from the mould, the moulding sand sticks to it.

To avoid sticking, parting sand is sprinkled on the pattern before it is embedded in the moulding sand

deliver molten metal into the mould cavity

The purpose of a gate is to Delivers molten metal into the mould cavity

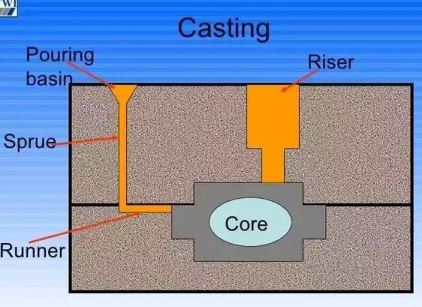

A proper method of gating system is that it leads the pure molten metal to flow through a ladle to the casting cavity, which ensures proper and smooth filling of the cavity. This depends on the layout of the gating channels too, such as the direction and the position of the runner, sprue and ingates.

feed the molten metal to the casting in order to compensate for the shrinkage

A riser, also known as a feeder, is a reservoir built into a metal casting mold to prevent cavities due to shrinkage.

Most metals are less dense as a liquid than as a solid so castings shrink upon cooling, which can leave a void at the last point to solidify.

all of these

Cores are used to Form internal cavities in the casting and Improve mould surfaceand used to Form a part of a green sand mould.

core is a device used in casting and moulding processes to produce internal cavities and reentrant angles .

The core is normally a disposable item that is destroyed to get it out of the piece

drop core

When a hole or cavity to be cored is not in line with the parting surface, then a drop core is used.