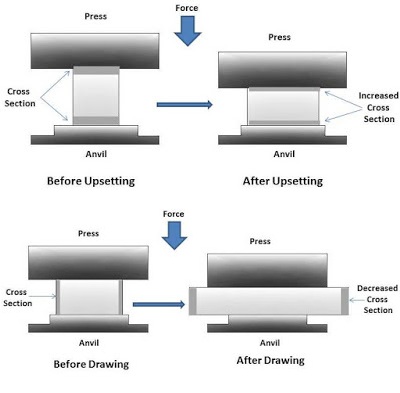

1)Drawing Down: Drawing down is a process of elongate the length and reduce the cross section area of work piece. Simply in this operation, the length of work piece increases and the cross section area decreases. In this process, a compressive force is applied at perpendicular direction of its length axis. If a tensile force is applied to change its length at parallel to its length axis, this process is known as wire drawing.

2) Upsetting: Upsetting is just opposite operation to drawing down. In this operation, the length of work piece decreases and its cross section area increases. In this process, a compressive force is applied at parallel direction to its length axis.

87) the drawing down is a process of ______ The cross-section of a bar.

Answer is:

reducing

Explanation:

Related Workshop Technology MCQ with Answers

Answer is:

punching

Explanation:

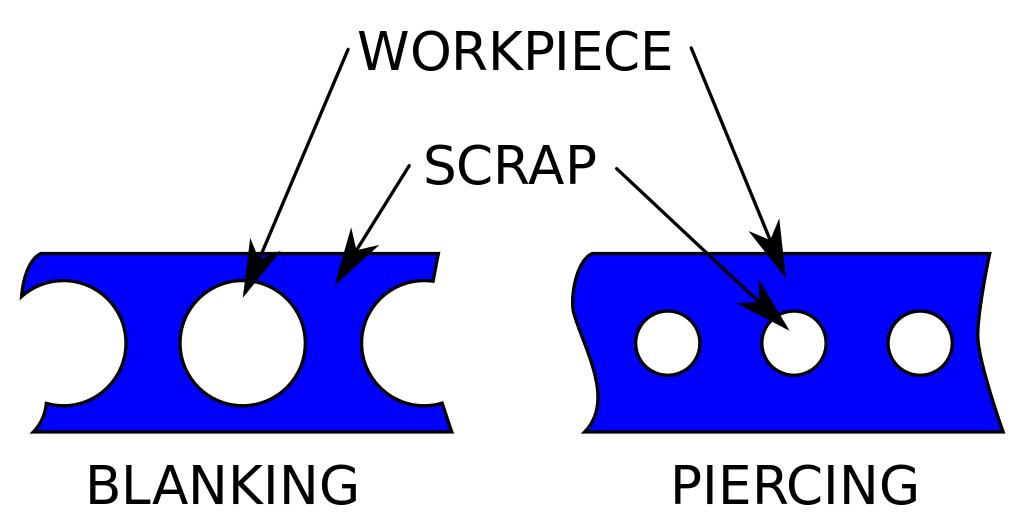

The operation of cutting a cylindrical hole in a sheet of metal by the punch and die is called punching.

Answer is:

a hole (other than cylindrical) in a sheet of metal by the punch and the die.

Explanation:

Piercing is an operation of cutting A hole (other than cylindrical) in a sheet of metal by the punch and the die.

Answer is:

blanking

Explanation:

Blanking and piercing are shearing processes in which a punch and die are used to modify webs. The tooling and processes are the same between the two, only the terminology is different: in blanking the punched out piece is used and called a blank; in piercing the punched out piece is scrap

Answer is:

removal of metal to the desired shape from the edge of a plate

Explanation:

Notching is the operation of Removal of metal to the desired shape from the edge of a plate.