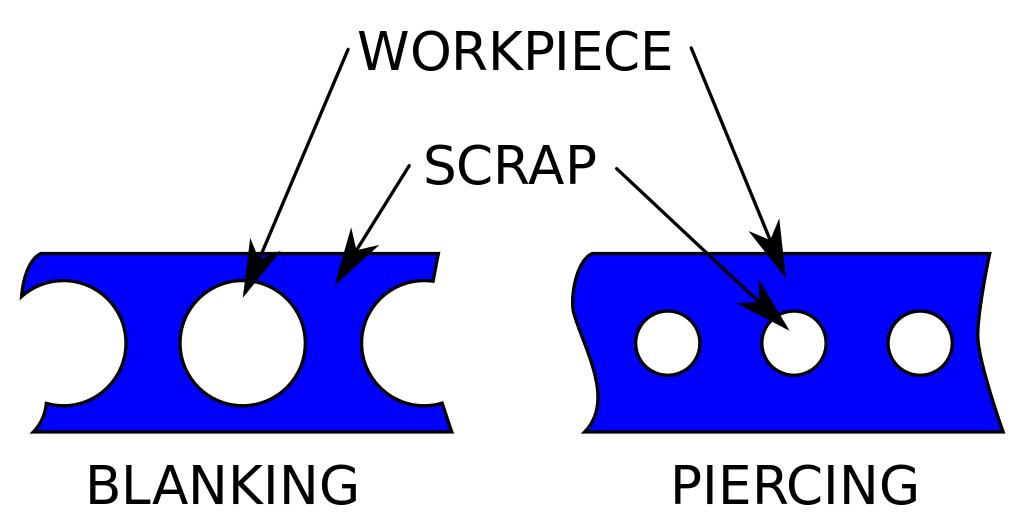

Blanking and piercing are shearing processes in which a punch and die are used to modify webs. The tooling and processes are the same between the two, only the terminology is different: in blanking the punched out piece is used and called a blank; in piercing the punched out piece is scrap

90) The operation of cutting a flat sheet to the desired shape is called

Answer is:

blanking

Explanation:

Related Workshop Technology MCQ with Answers

Answer is:

removal of metal to the desired shape from the edge of a plate

Explanation:

Notching is the operation of Removal of metal to the desired shape from the edge of a plate.

Answer is:

grinding the cutting edges sharp

Explanation:

In a sheet metal work the cutting force on the tool can be reduced by Grinding the cutting edges sharp.

Answer is:

press load is reduced

Explanation:

In sheet metal blanking, shear is provided on punches and dies so that Press load is reduced.

Answer is:

slitting

Explanation:

The operation of cutting a sheet of metal in a straight line along the length, is known as Slitting.