A progressive limit gauge that serves to determine whether the measured part is within prescribed limits of tolerance.

A progressive limit gauge has 'Go' and 'Not go' member on the same side of the gauge.

168) A progressive limit gauge has

Go' and 'Not go' member on the same side of the gauge

Related Workshop Technology MCQ with Answers

check the diameter of shafts or studs

ring gauge, is a cylindrical ring of a thermally stable material, often steel, whose inside diameter is finished to gauge tolerance and is used for checking the external diameter of a cylindrical object.

feeler

Feeler gauges are used:

– To check the gap between the mating parts

– To check and set the spark plug gaps

– To set the clearance between the fixture (setting block) and the cutter/tool for machining the jobs

– To check and measure the bearing clearance, and for many other purposes where a specified clearance must be maintained.

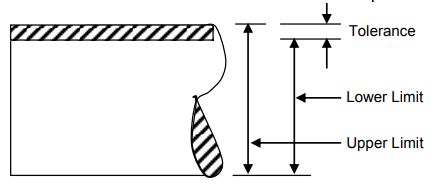

tolerance

Tolerance is defined as the difference between the maximum and the minimum sizes allowed in manufactured components.

upper deviation

Algebraic difference between a size and a corresponding basic size is called deviation. Limit deviations are upper and lower deviations. Algebraic difference of actual size with basic size is called actual deviation.

Upper Deviation: It is the algebraic difference between the maximum size and the basic size.

The upper deviation of a hole is represented by a symbol ES (Ecart Superior) and of a shaft, it is represented by es.

Lower Deviation: It is the algebraic difference between the minimum size and the basic size.

The lower deviation of a hole is represented by a symbol EI (Ecart Inferior) and of a shaft, it is represented by ei.