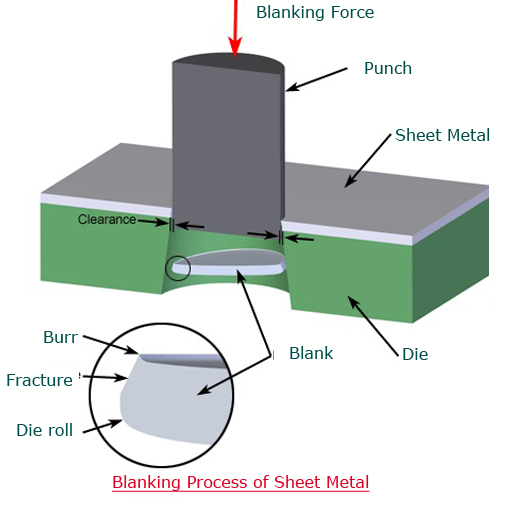

The operation of cutting of flat sheet to the desired shape is called blanking. In blanking operation, the clearance is provided on punch.

106) In blanking operation, the clearance is provided on

punch

Related Workshop Technology MCQ with Answers

changing the primary turns of the transformer

The current in electric resistance welding can be regulated by Changing the primary turns of the transformer.

copper

The electrodes are one of the most important factors in the resistance welding process but often the most abused. It is important to consider the electrode material, shape, size, tip profile and cooling.

The electrodes used in spot welding have a tip of Copper.

continuous spot welding process

Seam welding is a Continuous spot welding process.

seam welding is a variant of the basic resistance spot welding process.

In seam welding a series of overlapping nuggets is produced, usually by replacing the conventional spot welding electrodes by wheels that turn as the parts to be welded are fed between them.

multi-spot welding process

Projection welding is a modification of spot welding.

In this process, the weld is localized by means of raised sections, or projections, on one or both of the workpieces to be joined.