material movement is less

In fixed position layout

- Total production cost is less

- Material movement is less

- Capital investment is minimum

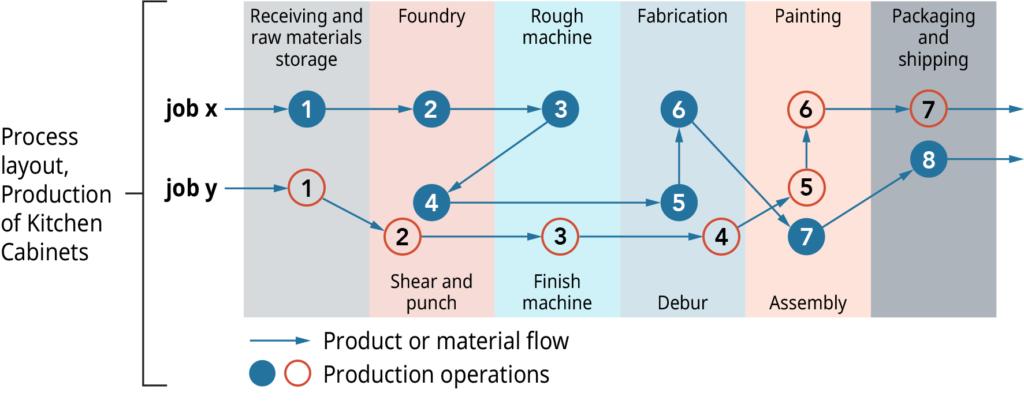

process layout

Process layout is a design for the floor plan of a plant which aims to improve efficiency by arranging equipment according to its function.

Process layout is also known as analytical layout.

In order to avoid excessive multiplication of facilities, the layout preferred is process layout.

In Process layout machining operation are performed in group together and not arranged according to any sequence.

standardization

Interchangeability can refer to Interchangeable parts, the ability to select components for assembly at random and fit them together within proper tolerances.

The interchangeability can be achieved by Standardization.

product layout

The production scheduling is simpler and high volume of output and high labour efficiency are achieved in the case of Product layout.