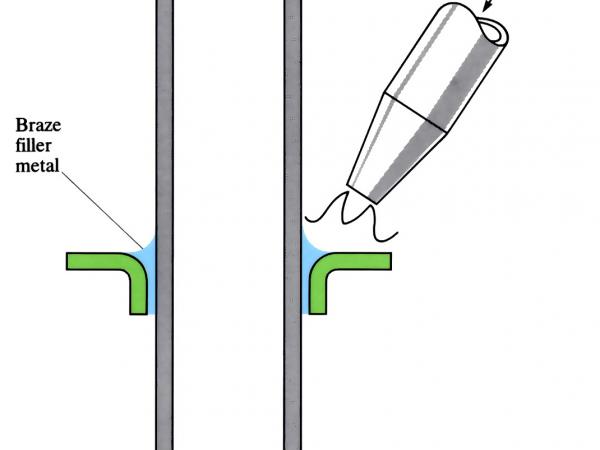

65) A process to make a permanent joint by joining two similar or dissimilar metals using any non-ferrous metal as the filler metal having a melting point below that of the base metal but higher than 450 degree celsius is called

brazing

Related KPSC ITI JTO Fitter Question Papers - 2018 with Answer Key

Seiton

5S Technique consists of following concepts

1) Seiri - organize - sort

2) Seiton - orderliness - set in order

3)Seiso - cleanliness - shine

4)Seiketsu - standardize - standardize

5)Shitsuke - discipline - sustain

Seiri - organize - sort - Eliminate whatever is not needed by separating needed tools, parts, and instructions from unneeded materials.

Seiton - orderliness - set in order - Organize whatever remains by neatly arranging and identifying parts and tools for ease of use.

Seiso - cleanliness - shine- Clean the work area by conducting a cleanup campaign.

Seiketsu - standardize - standardize - Schedule regular cleaning and maintenance by conducting seiri, seiton, and seiso daily.

Shitsuke - discipline - sustain - Make 5S a way of life by forming the habit of always following the first four S’s.

distance between the pivot and the point

0.8 mm

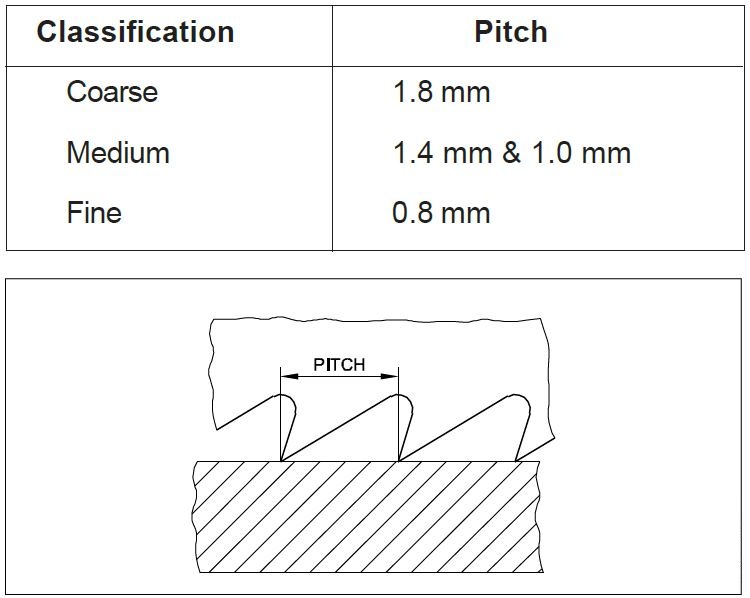

Pitch selection for Hacksaw Blade:

For soft materials such as bronze, brass, soft steel, cast iron, heavy angles etc. use a 1.8 mm pitch blade.

For tool steel, high carbon, high speed steel etc. use a 1.4 mm pitch. For angle iron, brass tubing, copper, iron pipe etc. use a 1 mm pitch blade.

For conduit and other thin tubing, sheet metal work etc. use a 0.8 mm pitch.