Normalizing involves heating steel to above 50°C above the upper critical temperature, (for hypo-eutectoid steel) and to 50°C above the lower critical temperature (for hyper eutectoid steel). Holding at this temperature for a shorter time to prevent grain growth and finally, cooling in air.

4) In the normalising process for hypo-eutectoid steel, the steel is heated to a temperature

above upper critical temperature line and cooled outside the furnace

Related KPSC ITI JTO Fitter Question Papers - 2018 with Answer Key

slowest cooling rate that converts 100% austenite to 100% martensite

Critical Cooling Rate - The minimum rate of continuous cooling just sufficient to prevent undesired transformations. For steel, the slowest rate at which it can be cooled form above the upper critical temperature to prevent the decomposition of austenite at any temperature above the Ms. The limiting rate at which austenite must be cooled to ensure that a particular type of transformation product is formed.

Critical cooling rate is slowest cooling rate that converts 100% austenite to 100% martensite

37% lead and 63% tin

Electricians solder consists of 37% lead and 63% tin.

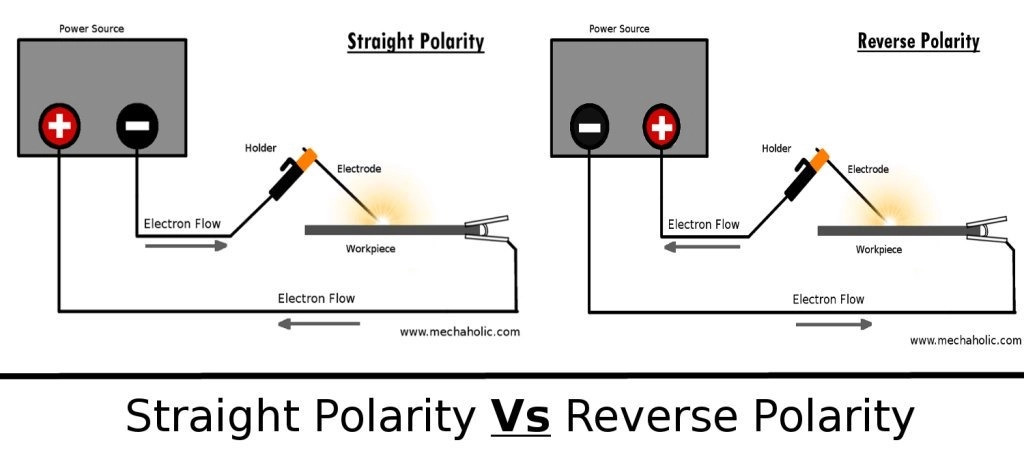

straight polarity is used

Direct Current Straight Polarity (DCSP) or Direct Current Electrode Negative (DCEN)—When electrode is connected with the negative terminal of the power source and base metals are connected with the positive terminal.

Metals with high melting temperature (such as stainless steel, titanium) can be suitably joined by DCSP.

Direct Current Reverse Polarity (DCRP) or Direct Current Electrode Positive (DCEP)—When base metals are connected with the negative terminal of the power source and electrode is connected with the positive terminal.

Metals with low melting temperature (such as copper, aluminum) can be suitably joined by DCSP.