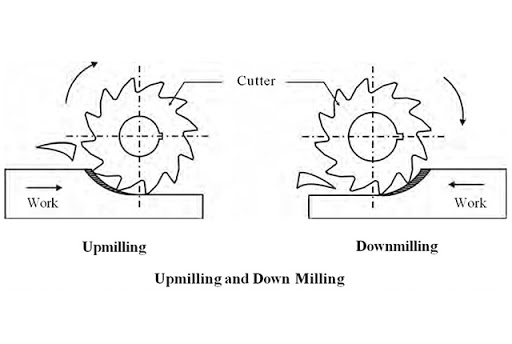

Up Milling is the process of removing metal by a cutter which is rotated against the direction of travel of the workpiece is called up-milling. It is also called conventional milling.

In up-milling, the chip thickness is minimum at the beginning of the cut and maximum at the end of cut. The cutting force varies from zero to maximum.

Down Milling is the process of removing metal by a cutter which is rotated in the same direction of travel of the workpiece is called down milling. It is also called climb milling.

In down milling, the chip thickness is maximum at the beginning of the cut and minimum at the end of cut. The cutting force varies from maximum to zero.

48) Which one of the milling process is best suitable?

Answer is:

Down milling

Explanation:

ISRO Technician-B Machinist Question Paper - 2015 (Set -1) with Answer Key

For more MCQ's Click HereRelated ISRO Technician-B Machinist Question Paper - 2015 (Set -1) with Answer Key

Answer is:

Stop program unconditionally

Explanation:

M00 - Program Stop (non-optional)

M01 - Optional Stop: Operator Selected to Enable

M02 - End of Program

M03 - Spindle ON (CW Rotation)

M04 - Spindle ON (CCW Rotation)

M05 - Spindle Stop

M06 - Tool Change

M07 - Mist Coolant ON

M08 - Flood Coolant ON

M09 - Coolant OFF

M17 - FADAL subroutine return

M29 - Rigid Tapping Mode on Fanuc Controls

M30 - End of Program, Rewind and Reset Modes

M97 - Haas-Style Subprogram Call

M98 - Subprogram Call

M99 - Return from Subprogram

Answer is:

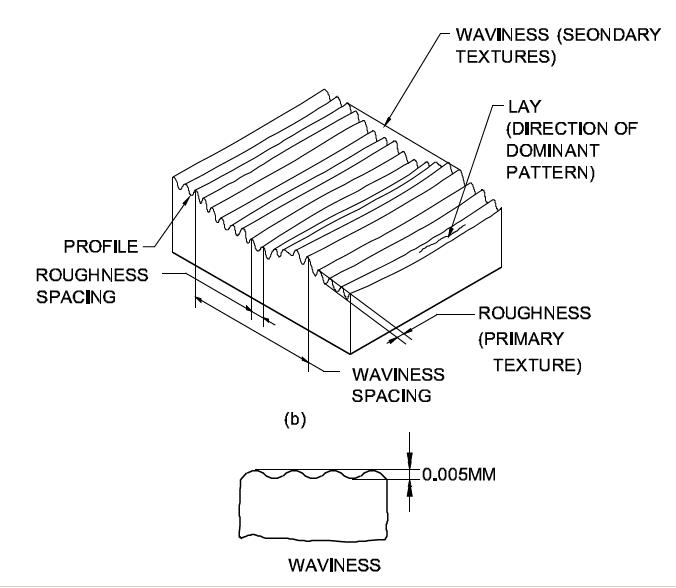

Waviness