Submerged-arc welding (SAW) is a common arc welding process that involves the formation of an arc between a continuously fed electrode and the workpiece. A blanket of powdered flux generates a protective gas shield and a slag (and may also be used to add alloying elements to the weld pool) which protects the weld zone.

4) Which welding method starting of welding done by using steel wool or iron powder?

SAW

Related Gas Metal Arc Welding MCQ with Answers

Argon and CO2

The two most common shielding gases for Flux-cored arc welding (FCAW) is a mix of 75 percent argon and 25 percent CO2.

2 types

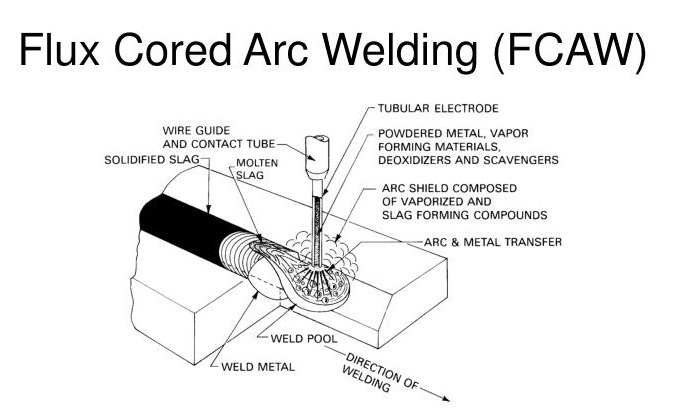

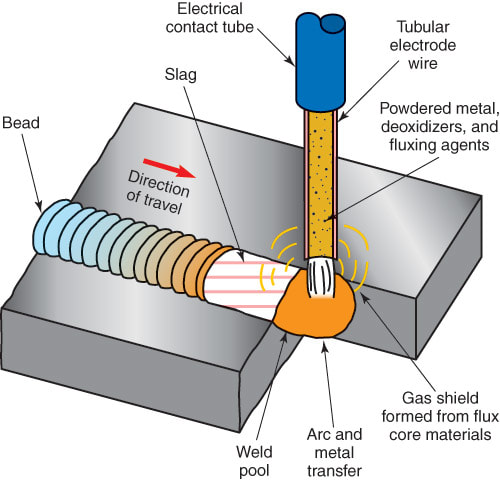

Flux cored arc welding (FCAW) is a semi-automatic arc welding process that is similar to metal active gas (MAG) welding. FCAW uses a continuous wire fed electrode, a constant-voltage welding power supply, and similar equipment to MAG welding.

There are two basic process variants; self shielded FCAW (without shielding gas) and gas shielded FCAW (with shielding gas). The difference in the two is due to different fluxing agents in the consumables, which provide different benefits to the user.

Tubular cored flux electrode

Tubular cored flux electrode provides protective slag in flux cored arc welding.

Helmet with filtered colour glass

A welding helmet, commonly referred to as a “hood,” is one of the most important pieces of personal protective equipment that a welder must have. An adequate helmet protects the eyes and skin not only from severe sparks, but also from potentially vision-damaging ultraviolet and infrared rays emitted by the arc.

Helmet with filtered colour glass is used to protect face from UV and Infra-red radiation during welding.