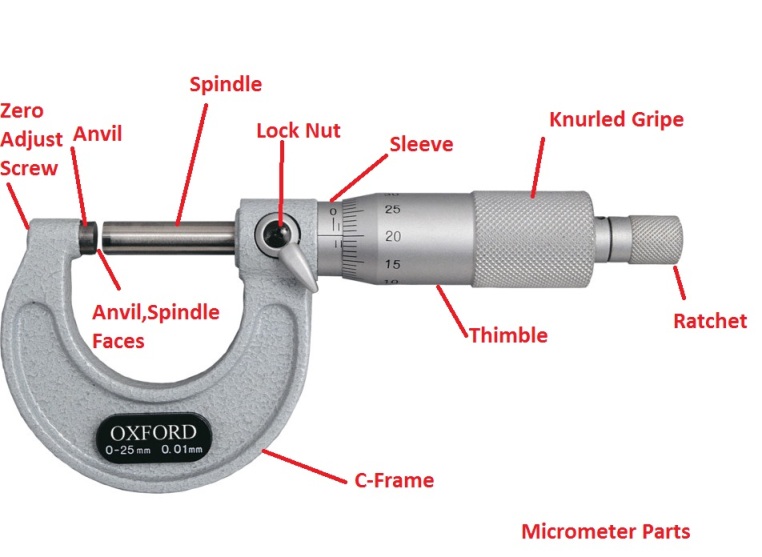

The spindle of an ordinary metric micrometer has 2 threads per millimetre, and thus one complete revolution moves the spindle through a distance of 0.5 millimetre. The longitudinal line on the sleeve is graduated with 1 millimetre divisions and 0.5 millimetre subdivisions.

Hence Metric outside micrometer has a threaded spindle with a pitch of 0.5 mm

18) Metric outside micrometer has a threaded spindle with a pitch of

0.5 mm

Related Measuring Instruments MCQ - Turner (Set-1) with Answers

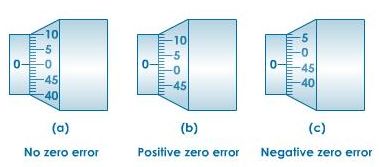

Zero on thimble and datum line on sleeve do not coincide when measuring faces are in contact

Zero error in micrometer occurs when zero on the thimble and datum line on sleeve do not coincide when measuring faces are in contact.

Lock the reading after setting it over the workpiece

The lock nut is simply a quarter turn nut that locks the spindle from turning. The sleeve contains the scale which is used to determine the measurement and the internal threads which allow the spindle to move.

Nut & bolt

The working principle of the Micrometer is based on screw and nut. (Rotational moment to linear moment) As we know as the screw rotates one revolution on the screw, then the screw moves linearly by one pitch distance

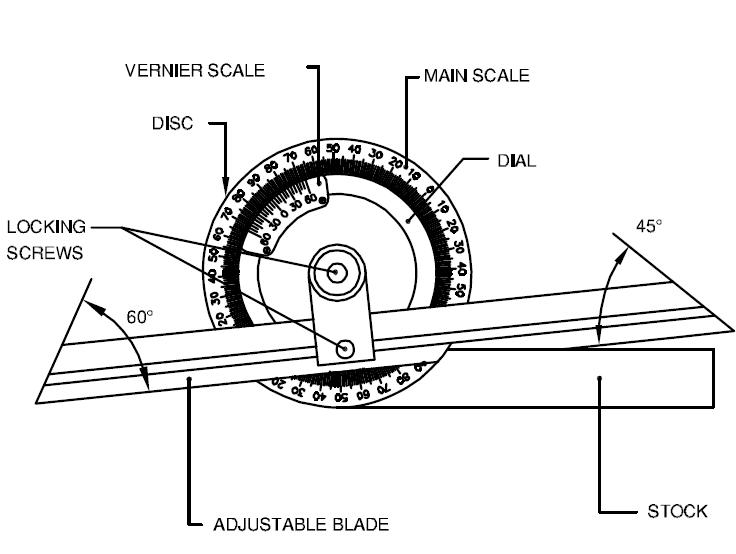

Vernier bevel protractor

The vernier bevel protractor is a precision instrument meant for measuring angles to an accuracy of 5 minutes.

The Least count of vernier bevel protractor is 5' (Five Minutes)

The value of each Vernier scale division of Vernier bevel protractor is 1 degree 55 minutes.

To get the least count of 5 minutes (5') in a vernier bevel protractor the 23 degree main scale is divided into 12 equal parts on vernier scale.

Following are the parts of a vernier bevel protractor.

Stock : – This is one of the contacting surfaces during the measurement of an angle. Preferably it should be kept in contact with the datum surface from which the angle is measured.

Dial:– The dial is an integrated part of the stock. It is circular in shape, and the edge is graduated in degrees.

Blade:- This is the other surface of the instrument that contacts the work during measurement. It is fixed to the dial with the help of the clamping lever. A parallel groove is provided in the centre of the blade to enable it to be longitudinally positioned whenever necessary.

Locking Screws:- Two knurled locking screws are provided, one to lock the dial to the disc, and the other to lock the blade to the dial.