Revolving Centres are Frictionless. Used for supporting heavy jobs and jobs revolving with high speeds. A high-speed steel inserted centre is supported by two bearings housed in a body. It is also called the revolving dead centre.

3) Which one of the following centres is suitable when workpiece held between centres is to be turned at high speed ?

Revolving centre

Related Lathe Accessories MCQ - Turner (Set-1) with Answers

60 Degree

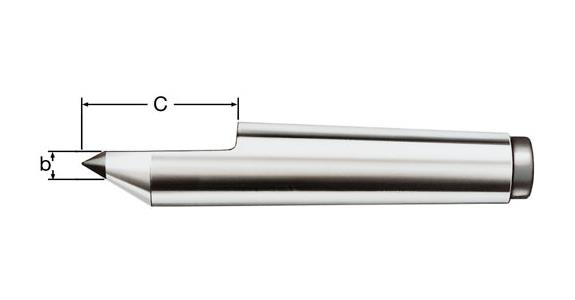

The centre, which is accommodated in the main spindle sleeve, is known as a ‘live centre’ and the centre fixed in the tailstock spindle is known as a dead centre. In construction, both centres are identical, made as one unit that consists of a conical point of 60° included angle, a body provided with a Morse taper shank and a tang.

To face the workpiece up to the end of the centre hole

Though it is termed as half centre, little less than half is relieved at the tip portion. Used while facing the job without disturbing the setting.

More friction

The dead centre is made out of high carbon steel, hardened and ground whereas the live centre need not have its conical tip hardened as it revolves with the work. A good lubricant should be used for the dead centre.

The diameter of the body of the chuck

The size of three-jaw chuck is specified by the diameter of the body of the chuck