When a surface of the wheel develops a smooth and shining appearance, it is said to be glazed. This indicates that the wheel is blunt, i.e. the abrasive grains are not sharp.

When such grinding wheels are used, there is a tendency to exert extra pressure in order to make the wheels cut.

Excessive pressure on the grinding wheel will lead to the fracture of the wheel, excessive heating of the wheel, weakening of bonding of the wheel and bursting of the wheel.

84) The cause for glazing of a grinding wheel is

Grain size is too fine and Wheel is hard

Related Cutting Tools MCQ - Turner (Set-1) with Answers

Vitrified

Vitrified Bond is the most widely used bond. It has high porosity and strength which makes this type of wheel suitable for high rate of stock removal. It is not adversely affected by water, acid, oils or ordinary temperature conditions.

Silicon carbide

Artificial abrasives are silicon carbide and aluminium oxide.

Silicon carbide is denoted with "C"

Aluminium oxide is denoted with "A"

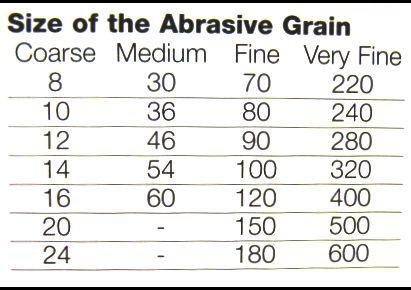

Medium

As per Indian Standards the grain size 46 comes under the group "Medium"

Medium

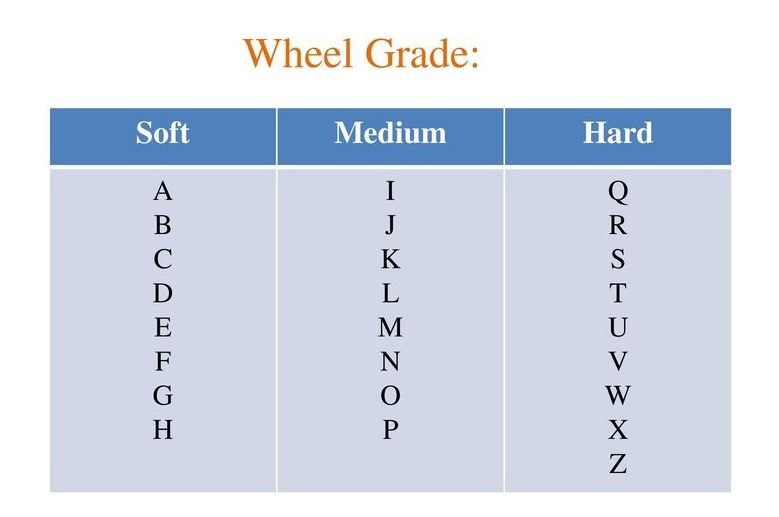

As per Indian Standards the 'M' grade of grinding wheel comes under the group Medium.

The term grade as applied to a grinding wheel refers to the tenacity with which the bond holds the abrasive grains in place, and does not refer to the hardness of the abrasive.

A wheel from which the grains are released rapidly during the grinding operation is called soft grade, whereas wheel that retains the grains more securely is called hard grade