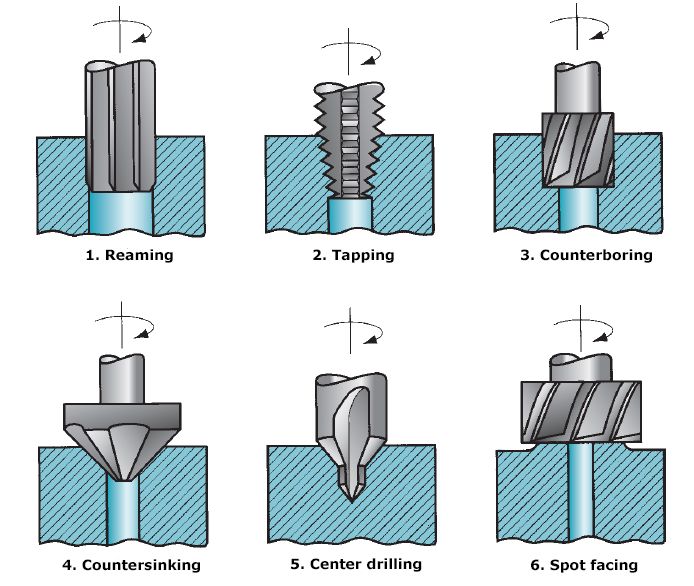

Spot facing is a machining operation for producing a flat seat for bolt head, washer or nut at the opening of a drilled hole. The tool is called a spot facer or a spot facing tool. Spot facing is similar to counter-boring, except that it is shallower. Tools that are used for counter-boring can be used for spot facing as well.

44) Spot-facing is done to

Answer is:

Make surface flat so that bolt head can take proper seat on the surface

Explanation:

Related Cutting Tools MCQ - Turner (Set-1) with Answers

Answer is:

Preventing digging of the ends of cutting edge

Answer is:

Material to be drilled

Explanation:

The point angle of a general purpose (standard) drill is 118°. This is the angle between the cutting edges (lips). The angle varies according to the hardness of the material to be drilled.

Answer is:

118 Degree

Explanation:

For general purpose use point angle of twist drill is 118 Degree.