Sine bars are rectangular bar made of stabilized chromium steel. The surfaces are accurately finished by grinding and lapping.

Two precision rollers of the same diameter are mounted on either end of the bar. The centre line of the rollers is parallel to the top face of the sine bar. There are holes drilled across the bar. This helps in reducing the weight, and also it facilitates clamping of sine bar on angle plate.

The length of the sine bar is the distance between the centres of the rollers. The commonly available sizes are 100 mm, 200 mm, 250 mm and 500 mm. The size of a sine bar is specified by its length.

28) A sine bar is made with four or five equally-spaced holes on its body. The purpose of these holes is to

Answer is:

Handle the sine bar easily

Explanation:

Related Gauges MCQ - Machinist(Set-1) with Answers

Answer is:

300 mm

Answer is:

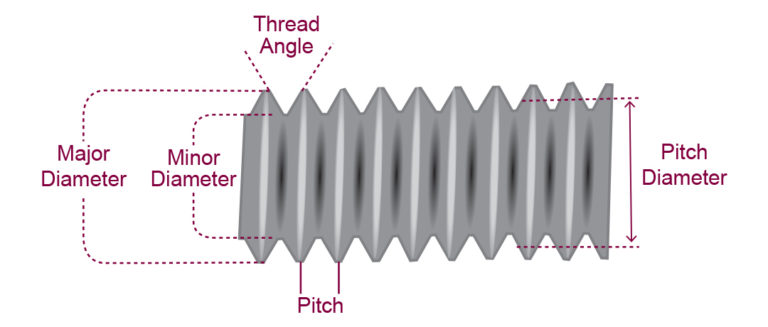

Pitch diameter

Answer is:

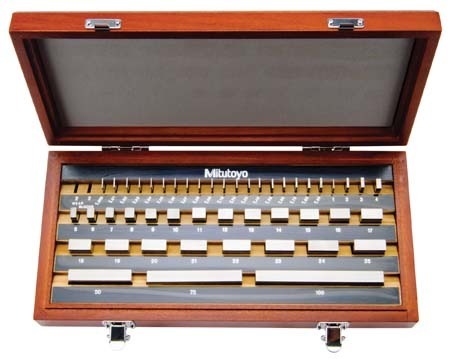

Grade 00

Explanation:

Slip gauges are graded according to their accuracy as Grade 0, Grade I and Grade II.

Grade 0 is used in laboratories and standard room which serves as standard for periodically checking the accuracy of Grade I and Grade II gauges.

Grade I is of higher accuracy and used in inspection departments.

Grade II is intended for use in workshops during the actual production of components, tools and gauges.