105) Which among the following is NOT the cause for loading of grinding wheel ?

Answer is:

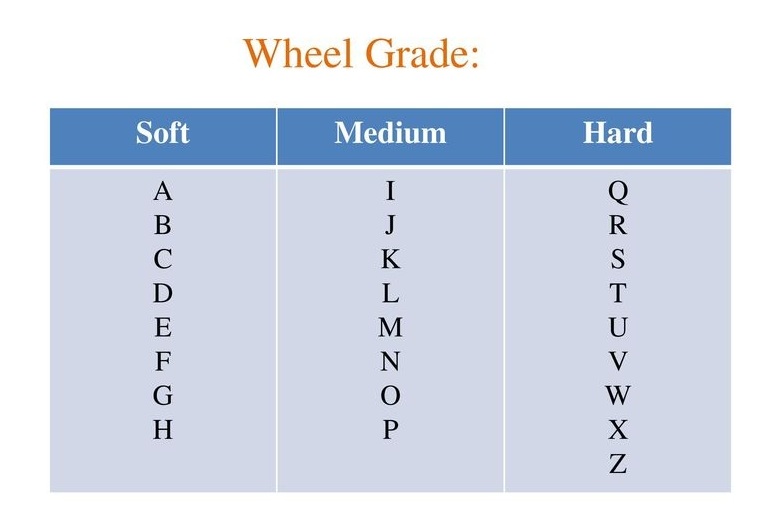

Proper grain size and grade of wheel

Related Cutting Tools MCQ - Machinist(Set-1) with Answers

Answer is:

Floating reamer

Explanation:

Floating reamer can adjust itself in case of slight misalignment when fitted on a tailstock.

Answer is:

Larger bevel lead for the cutting edge

Answer is:

Grade of wheel is too hard

Answer is:

Grinding wheel's speed is too high and work speed is low

Explanation:

When the cutting edge of a grinding wheel takes a glass like appearance due to wear of abrasive grains then it is called glazing of the grinding wheel. Glazing decreases the rate of grinding. The glazing in the grinding wheels takes place when the wheel is too hard or it revolves at a very high speed.

Thus the glazing may be decreased by using a softer wheel or decreasing the wheel speed.

The process of changing the shape of grinding wheel as it becomes worn due to breaking away of the abrasive and bond is called truing.

The process of improving the cutting action of the grinding wheel is called dressing.