Upper Limit = Basic Size +ES = 50+0.025=50.025

Lower Limit = Basic Size + EI = 50+0.002 = 50.002

2) Limits of 50 mm hole is ES=+0.025 and EI =+0.002 mm. The maximum and minimum hole sizes will be:

Max. 50.025 mm ; Min. 50.002 mm

Related Limits and Fits MCQ with Answers

21 classes of fits and 16 grades of tolerances

British standard limit system consists of 21 classes of fits and 16 grades of tolerances.

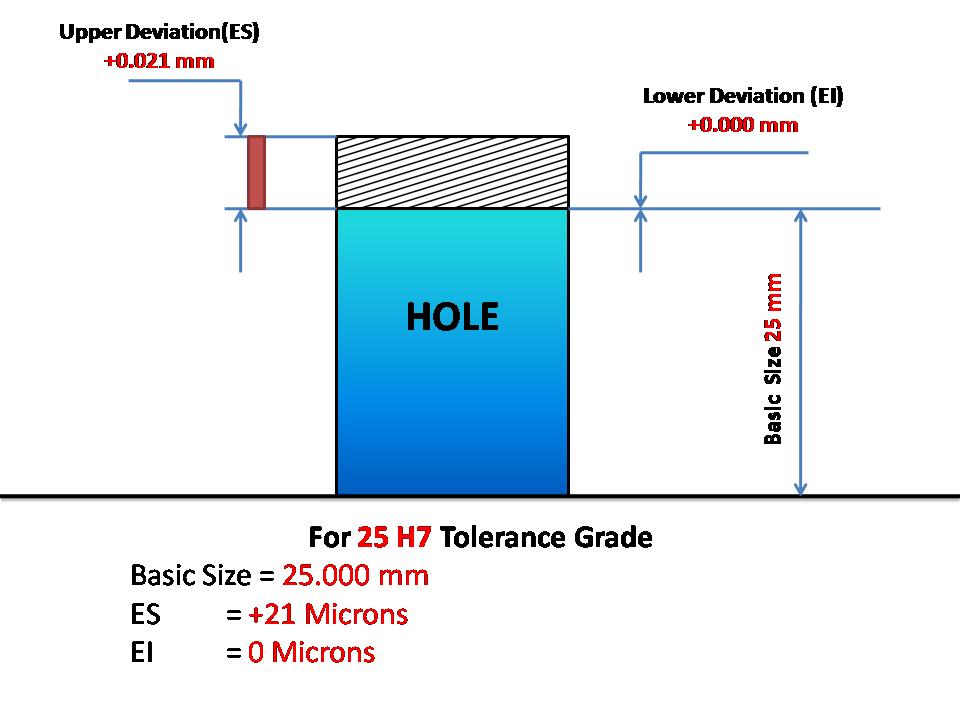

25.00 mm

A dimension is stated as Dia 25 H7 in a drawing. The lower limit is 25.00 mm.

For 25 H7 Tolerance Grade

Basic Size = 25.000 mm

ES = +21 Microns = 0.021 mm

EI = 0 Microns = 0.000 mm

Hence

Lower limit = Basic Size + EI = 25.000 + 0.000 = 25.000 mm

Upper Limit = Basic Size + ES = 25.000 + 0.021 = 25.021 mm

Hence A dimension is stated as Dia 25 H7 in a drawing. The lower limit is 25.000 mm.

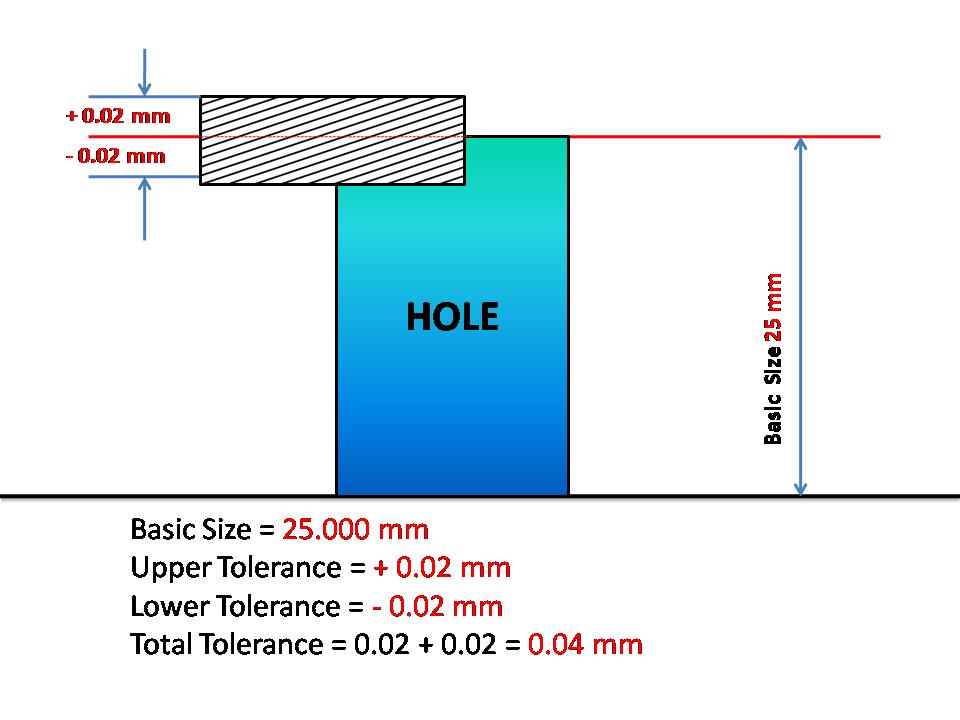

0.04 mm

A dimension is stated as 25 +/-0.02 mm in a drawing. Then

Basic Size = 25.000 mm

Upper Tolerance = + 0.02 mm

Lower Tolerance = - 0.02 mm

Total Tolerance = 0.02 + 0.02 = 0.04 mm

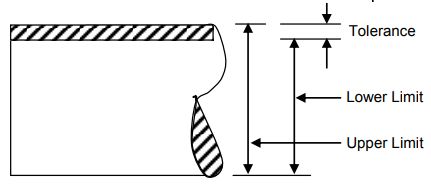

Tolerance

Tolerance is defined as the difference between the maximum and the minimum sizes allowed in manufactured components.