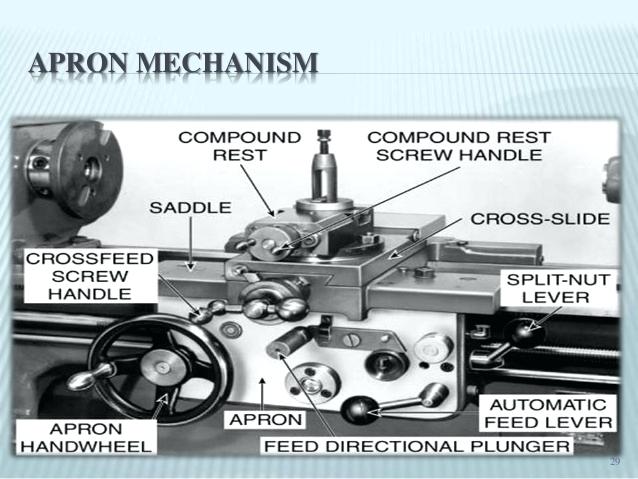

The horizontal feed, cross feed and screw cutting movement in a lathe is controlled by apron.

3) The Horizontal feed, cross feed and screw cutting movement in a lathe is controlled by

Apron

Related Lathe Construction MCQ with Answers

Headstock spindle

A faceplate is held at headstock spindle of lathe.

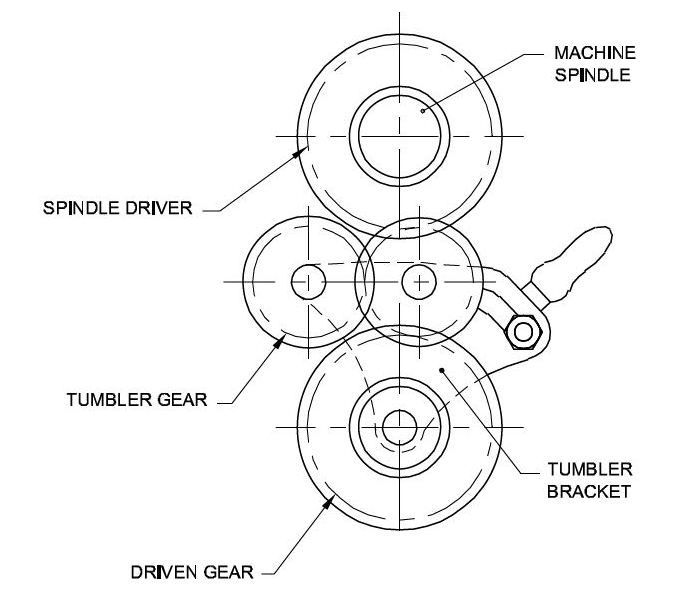

Changing the direction of rotation of the lead screw

Tumbler gear mechanism is used to change the direction of lead screw and feed rod in lathe machines. By Engaging tumbler gear, the carriage can be moved automatically from tailstock end to headstock

Just below the nose of the headstock spindle

Gap or extension-type lathes are similar to toolroom lathes except that gap lathes can be adjusted to machine larger diameter and longer workplaces The operator can increase the swing by moving the bed a distance from the headstock, which is usually one or two feet.

In a gap bed lathe, the gap is provided just below the nose of the headstock spindle.

Tailstock

The tailstock of a lathe can be used for drilling, with the aid of a drill chuck attachment. The drill chuck has a morse taper shaft which can be push into the shaft of the tailstock, locking it in position. The usual starting point for drilling with a centre lathe is to use a countersink bit.