Remove induced stresses

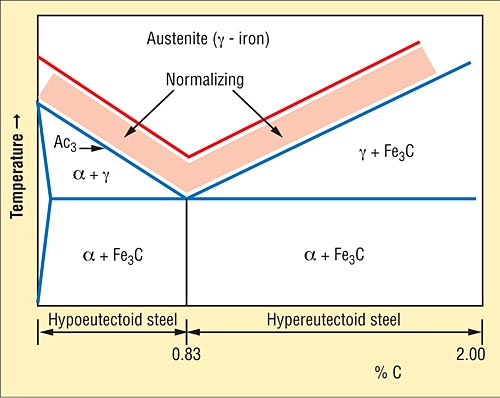

Purpose of normalizing steel is to

To produce fine grain size in the metal.

- To remove stresses and strains formed in the internal structure due to repeated heating and uneven cooling

- hammering.

- To reduce ductility.

- To prevent warping.

Annealing

The annealing process is carried out by heating the steel above the critical range, soaking it for sufficient time to allow the necessary changes to occur, and cooling at a predetermined rate, usually very slowly, within the furnace.

It was suddenly cooled in brine

It was suddenly cooled in brine in heat treatment, this is the main reason for the component to crack after heat treatment.

Low-carbon steel parts

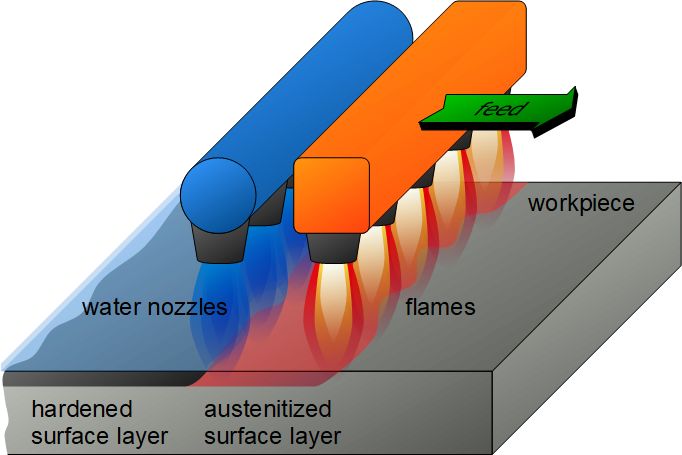

Case-hardening or surface hardening is the process of hardening the surface of a metal object while allowing the metal deeper underneath to remain soft, thus forming a thin layer of harder metal (called the "case") at the surface.

Normally Low carbon steel parts are subjected to case hardening process.

5) To reduce internal stresses of a hardened tool, the method of heat treatment generally applied is

Tempering

The tempering process consists of heating the hardened steel to the appropriate tempering temperature and soaking at this temperature, for a definite period.