Balancing of wheel is done to equalize the weight in every position of the wheel.

8) Balancing of wheel is done to

Equalize the weight in every position of the wheel

Related Grinding MCQ with Answers

All of the above

Grinding fluids are used to

Reduce the friction between the wheel face and the job

Wash away chips

Prevent loading of wheel

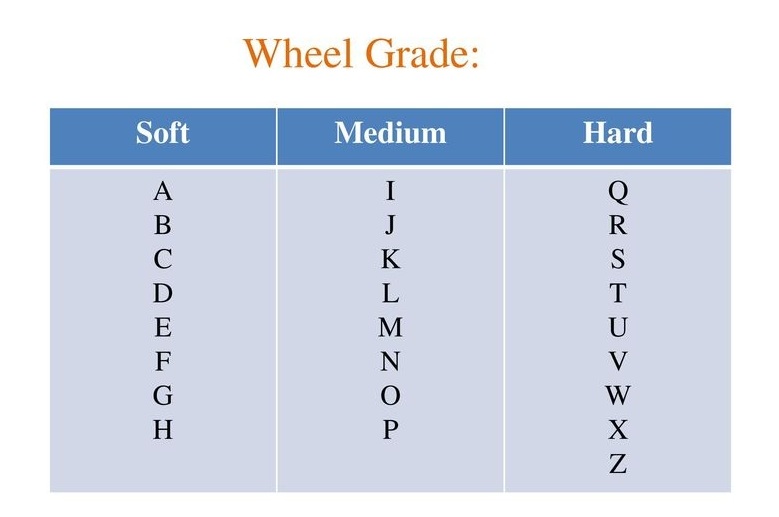

Hard

For cylindrical grinding a small diameter work with fairly large wheel Hard grade wheel is used.

Improper dressing of wheel

When the cutting edge of a grinding wheel takes a glass-like appearance due to wear of abrasive grains then it is called glazing of the grinding wheel. Glazing decreases the rate of grinding. The glazing in the grinding wheels takes place when the wheel is too hard or it revolves at a very high speed.

Thus the glazing may be decreased by using a softer wheel or decreasing the wheel speed.

The process of changing the shape of grinding wheel as it becomes worn due to breaking away of the abrasive and bond is called truing.

The process of improving the cutting action of the grinding wheel is called dressing.

All of the above

The effect of using a glazed or loaded wheel is

More heat generation

Poor surface finish

Excessive cutting pressure between the wheel face and the work surface