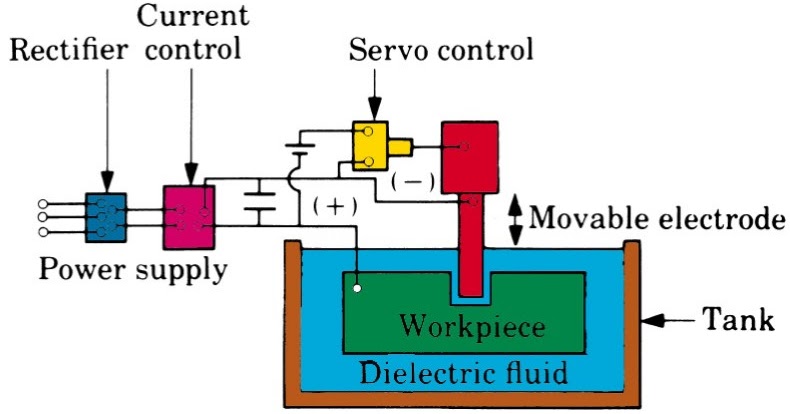

Electro Discharge Machining (EDM) In electro discharge machining the metal is removed by erosion caused by rapidly recurring spark discharges between the tool (cathode) and work (anode) separated by flooded dielectric fluid through a small gap.

The dielectric is used to control the spark discharges, to help in the movement of the sparks and to act as coolant. The tool is made of cast iron, brass, copper and copper tungsten alloy. The electro discharge machining can machine hardest materials and produces high degree of surface finish.

In EDM process the work piece is connected to Anode and the electrode connected to the cathode.

12) The function of dielectric in EDM process is to

Answer is:

All of the above

Explanation:

Related Manufacturing Technology MCQ with Answers

Answer is:

Rate of metal removal decreases

Answer is:

Increasing current density and decreasing frequency of sparks.

Answer is: