Centrifugal casting is a process that delivers components of high material soundness. . By spinning a mold while molten metal is poured into it, centrifugal force acts to distribute the molten metal in the mold at pressures approaching 100 times the force of gravity.

77) In a centrifugal casting method

Answer is:

no core is used

Explanation:

Related Workshop Technology MCQ with Answers

Answer is:

symmetrical shape about horizontal axis

Explanation:

The centrifugal casting method, is used for casting articles of Symmetrical shape about horizontal axis.

Answer is:

shell molding

Explanation:

Shell moulding is an expendable mold casting process that uses a resin covered sand to form the mold.

the most preferred process for casting gas turbine blades is Shell moulding.

Answer is:

results in a mismatching of the top and bottom parts of a casting

Explanation:

Shift refers to a defect caused by a sidewise displacement of the mold cope relative to the drag, the result of which is a step in the cast product at the parting line.

Shift is a casting defect which Results in a mismatching of the top and bottom parts of a casting.

Answer is:

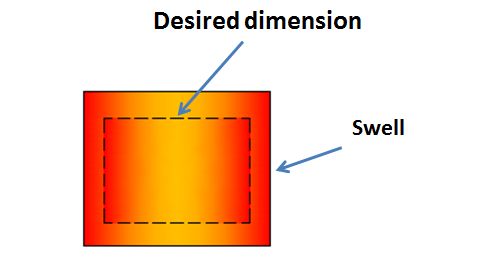

swell

Explanation:

Swell is the enlargement of the mold cavity because of the molten metal pressure, which results in localized or overall enlargement of the casting.