Patterns come in many materials, including wood, metal, plastics, and wax. The pattern material is chosen based on the casting volume and process used. Wood and metal patterns are usually used with sand casting, while wax is rarely used for anything but investment casting.

38) Metal patterns are used for

large scale production of castings

Related Workshop Technology MCQ with Answers

all of these

Aluminum Patterns are the good choice for high quality, long lasting Production. Compared to other pattern materials, Aluminium is highly resistant to the abrasive sand.

cope

Cope and Drag refer to the two halves (top and bottom, respectively) of a Pattern or Mold that is used in the Green Sand Casting Method.

bottom part

Cope and Drag refer to the two halves (top and bottom, respectively) of a Pattern or Mold that is used in the Green Sand Casting Method.

draft allowance

Pattern Allowances:

A pattern is always made larger than the required size of the casting considering the various allowances. These are the allowances which are usually provided in a pattern.

1.Shrinkage or Contraction allowance:

The various metals used for casting contract after solidification in the mould. Since the contraction is different for different materials, therefore it will also differ with the form or type of metal.

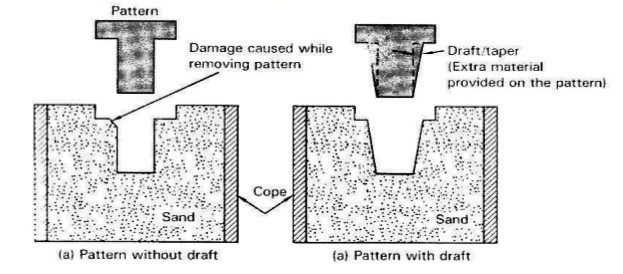

2.Draft allowance

It is a taper which is given to all the vertical walls of the pattern for easy and clean withdraw of the pattern from the sand without damaging the mould cavity. It may be expressed in millimeters on a side or in degrees. The amount of taper varies with the type of patterns. The wooden patterns require more taper than metal patterns because of the greater frictional resistance of the wooden surfaces.

3.Finish or machining allowance

The allowance is provided on the pattern if the casting is to be machined. This allowance is given in addition to shrinkage allowance. The amount of this allowance varies from 1.6 to 12.5 mm which depends upon the type of the casting metal, size and the shape of the casting. The ferrous metals require more machining allowance than non ferrous metals.

4.Distortion or camber allowance

This allowance is provided on patterns used for casting of such design in which the contraction is not uniform throughout.

5.Rapping or shaking allowance

This allowance is provided in the pattern to compensate for the rapping of mould because the pattern is to be rapped before removing it from the mould.