A slightly oxidizing flame is used in torch brazing of steel and cast iron. A stronger oxidizing flame is used in the welding of brass or bronze.

134) The brass and bronze are welded by ______ flame.

oxidizing

Related Workshop Technology MCQ with Answers

hard surfacing materials such as satellite

A carburizing flame is advantageous for welding high carbon steel and hard facing such nonferrous alloys as nickel and Monel.

Carburising flame is used to weld Hard surfacing materials such as stellite

from right to left

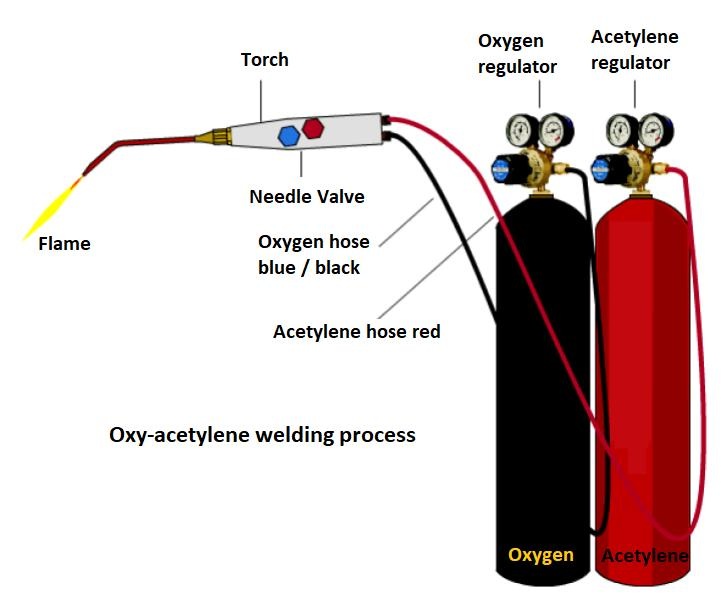

The usual gas welding techniques in Oxy-acetylene welding are as follows:

1.Leftward or fore-hand welding:- In this method, the welding torch is held in the operator’s right hand, the tip pointing towards the left and the weld is made from right to left. The torch makes an angle of 60°- 70° with the plate and the welding rod makes an angle of 30° - 40°. The plates above 6 mm thickness are not economical to weld with this method.

2.Right-ward or back-hand welding:- In this method, the welding torch is held in the right hand and the filler rod in the left-hand. The welding begins at the left hand end of the joint and proceeds towards the right. The torch makes an angle of 40° - 50° with the plate and the welding rod makes an angle of 30° - 40°. This method is better and economical for plates over 6 mm thickness.

3.Vertical welding:- The vertical welding may be carried out either by the left-ward technique or by the right-ward technique. The great advantage of vertical welding is that the plate edge preparation is not required up-to 16 mm thickness.

4.Linde welding:-It is a special welding technique in which the use of Oxy-acetylene flame with excess acetylene is made and the right-ward technique is used.

vertical

In vertical welding, the weld may be made either from left to right or from right to left.

black color

The oxygen cylinder is usually painted with Black colour.