The stress in the flange region during the deep drawing process is a combination of radial tensile drawing stress and a tangential compressive stress.

The blank-holder at the top of the workpiece exerts a compressive force at the upper surface of the blank during the drawing process.

13) During drawing operation, the states of stress in cup would include

compressive stress in the flange and tensile stress in the wall

Related Workshop Technology MCQ with Answers

bending and stretching

The mode of deformation of the metal during spinning is Bending and stretching.

uniform solid and hollow sections

The metal extrusion process is generally used for producing Uniform solid and hollow sections

Extrusion is a process used to create objects of a fixed cross-sectional profile.

A material is pushed through a die of the desired cross-section.

The extrusion process can be done with the material hot or cold

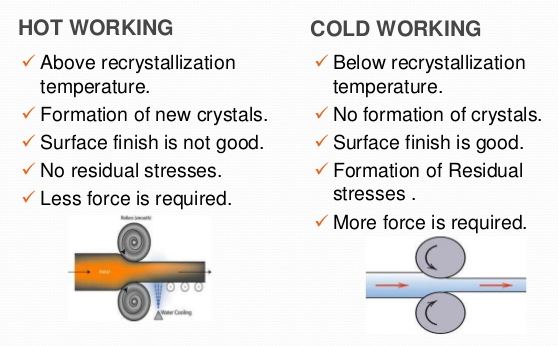

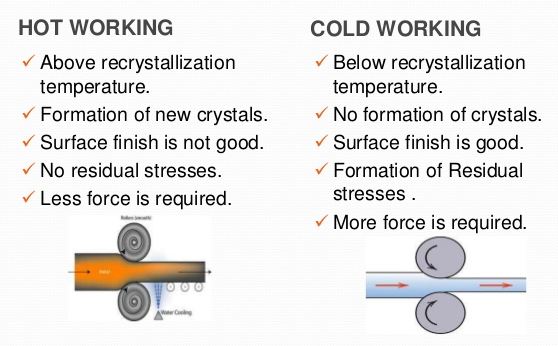

below the recrystallisation temperature

The working of metals below their recrystallisation temperature is known as cold working. Most of the cold working processes are performed at room temperature. The cold working distorts the grain structure and does not provide an appreciable reduction in size. It requires much higher pressure than hot working. The extent to which a metal can be cold worked depends upon its ductility. The higher the ductility of the metal, the more it can be cold worked. It also increases tensile strength , yield strength and hardness of steel but lowers its ductility. The increase in hardness due to cold working is called work-hardening.

The cold working of metals is carried out below the recrystallisation temperature.

work-hardening

Work hardening also called cold working is one of the process of increasing the strength of the material.

Work hardening is a very useful strengthening mechanism that occurs particularly in metallic materials through plastic deformation.