Submerged arc welding is an arc welding process in which heat is generated by an arc which is produced between bare consumable electrode wire and the workpiece.

118) In submerged arc welding, an arc is produced between a

bare metal electrode and the work

Related Workshop Technology MCQ with Answers

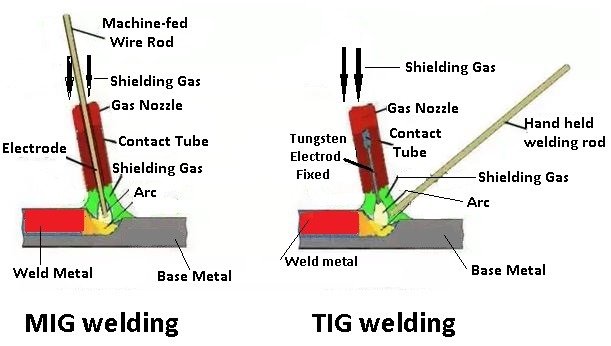

MIG arc welding

MIG welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two base materials together. A shielding gas is also sent through the welding gun and protects the weld pool from contamination. In fact, MIG stands for metal inert gas.

either (a) or (b)

In TIG arc welding, The weld area and electrode is protected from oxidation or other atmospheric contamination by an inert shielding gas argon or helium.

direct current with straight polarity is used

In welding copper alloys with TIG arc welding Direct current with straight polarity is used.

Copper and copper-base alloys have specific properties which make them widely used. Their high electrical conductivity enable their use in the electrical industries, and the corrosion resistance of certain alloys makes them very useful in the process industries.

TIG welding

Gas tungsten arc welding (GTAW), or tungsten/inert-gas (TIG) welding, is a manual welding process that uses a non-consumable electrode made of tungsten, an inert or semi-inert gas mixture, and a separate filler material.