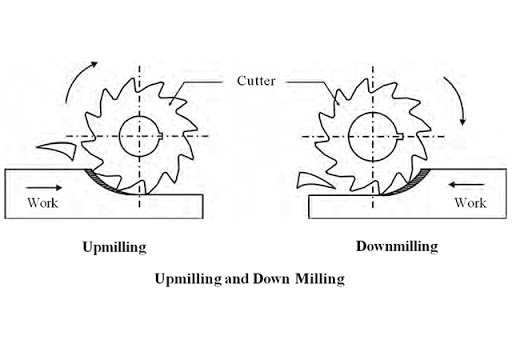

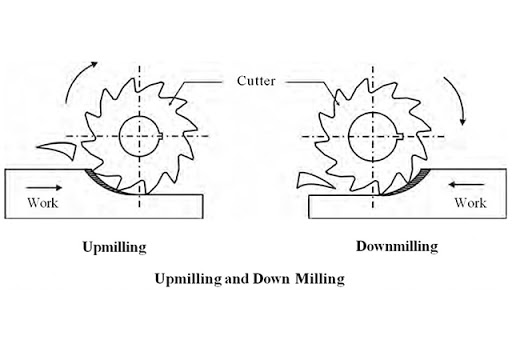

Up Milling

The process of removing metal by a cutter which is rotated against the direction of travel of the workpiece is called up-milling. It is also called conventional milling. In up-milling, the chip thickness is minimum at the beginning of the cut and maximum at the end of cut. The cutting force varies from zero to maximum.

Down Milling

The process of removing metal by a cutter which is rotated in the same direction of travel of the workpiece is called down milling. It is also called climb milling. In down milling, the chip thickness is maximum at the beginning of the cut and minimum at the end of cut. The cutting force varies from maximum to zero.

248) In ______operation, the chip thickness is minimum at the beginning of the cut and it reaches to the maximum when the cut terminates.

conventional milling

Related Production Engineering MCQ with Answers

down milling

Up Milling is the process of removing metal by a cutter which is rotated against the direction of travel of the workpiece is called up-milling. It is also called conventional milling.

In up-milling, the chip thickness is minimum at the beginning of the cut and maximum at the end of cut. The cutting force varies from zero to maximum.

Down Milling is the process of removing metal by a cutter which is rotated in the same direction of travel of the workpiece is called down milling. It is also called climb milling.

In down milling, the chip thickness is maximum at the beginning of the cut and minimum at the end of cut. The cutting force varies from maximum to zero.

differential indexing

inter-related to index change gear ratio

all of these

The purpose of jigs and fixtures is to

* increase machining accuracy

* facilitate interchangeability

* decrease expenditure on quality control