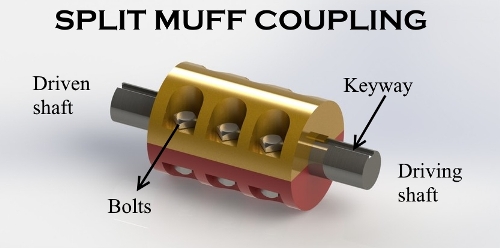

Muff Coupling / Sleeve Coupling is the simplest type of rigid coupling, consists of a hollow cylinder whose inner diameter is same as shaft. It is fitted over the ends of the two shafts by means of a gib head key. The power is transmitted from one shaft to the other shaft by means of a key and a sleeve or muff.

The sleeve or muff coupling is designed as a hollow shaft.

1) The sleeve or muff coupling is designed as a

Answer is:

hollow shaft

Explanation:

Related Machine Design MCQ with Answers

Answer is:

Wrong

Explanation:

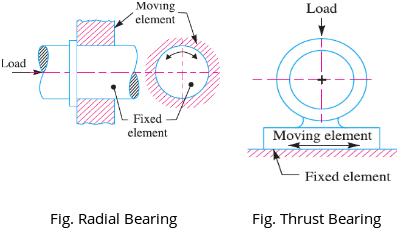

Zero film bearings are those which operate without the presence of lubricant. The name itself elucidates that there is no film of lubricant present between contact surfaces. There is a direct contact between them. For example, sliding or rolling contact.

Answer is:

high efficiency

Explanation:

Screws used for power transmission should have high efficiency.

Answer is:

Correct

Explanation:

When rivets are unable to shear of in tensile load they are under in crushed due to this rivet hole becomes of an oval shape. Due to this, no of rivets under shear shall be equal to the no of rivets under crushing.

Answer is:

crown bevel gears

Explanation:

When bevel gears connect two shafts whose axes intersect at an angle greater than a right angle and one of the bevel gears has a pitch angle of 90 Degree, then they are known as crown bevel gears.