In process layout

- Handling and backtracking of materials is too much

- Production control is more difficult and costly

- Routing and scheduling is more difficult

89) In process layout

all of the above

Related Industrial Engineering MCQ with Answers

fixed position layout

Fixed position layout is also known as Static product layout.

In Fixed position layout, personnel, supplies, and equipment are brought to the site where the product will be assembled, rather than the product being moved through an assembly line or set of assembly stations.

material movement is less

In fixed position layout

- Total production cost is less

- Material movement is less

- Capital investment is minimum

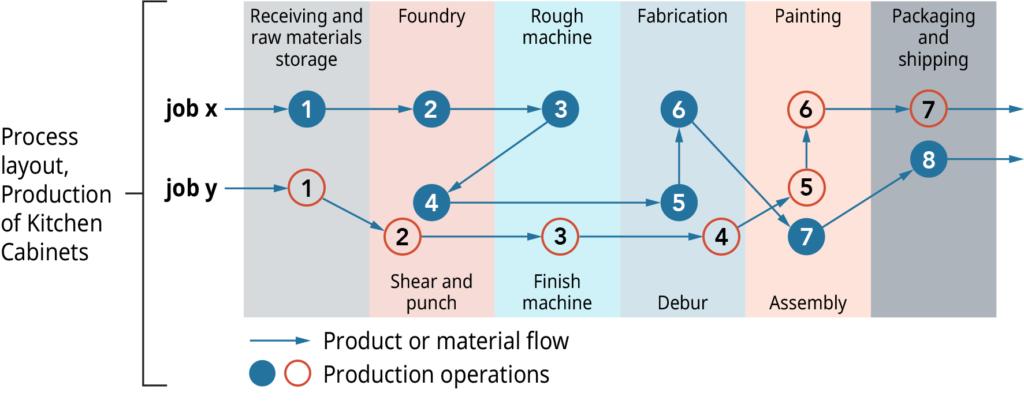

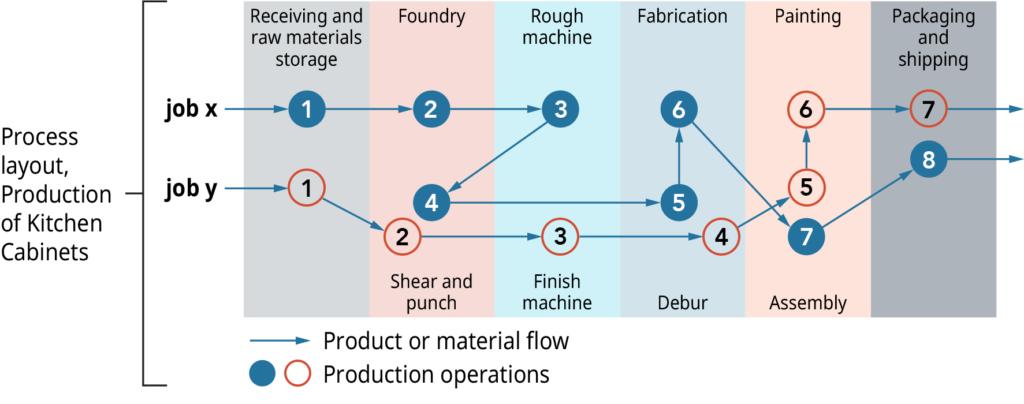

process layout

Process layout is a design for the floor plan of a plant which aims to improve efficiency by arranging equipment according to its function.

Process layout is also known as analytical layout.

In order to avoid excessive multiplication of facilities, the layout preferred is process layout.

In Process layout machining operation are performed in group together and not arranged according to any sequence.